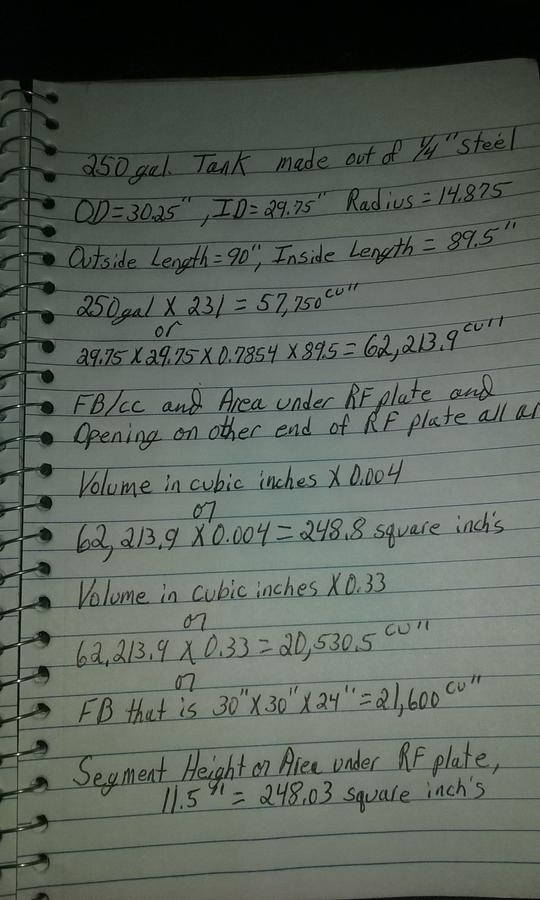

here is what I have come up with my build as far as numbers. Would like to get some feed back for this is my first time trying to build a smoker and this forum has been a huge help.

numbers for a 250gal propane tank

- Thread starter fire phil

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

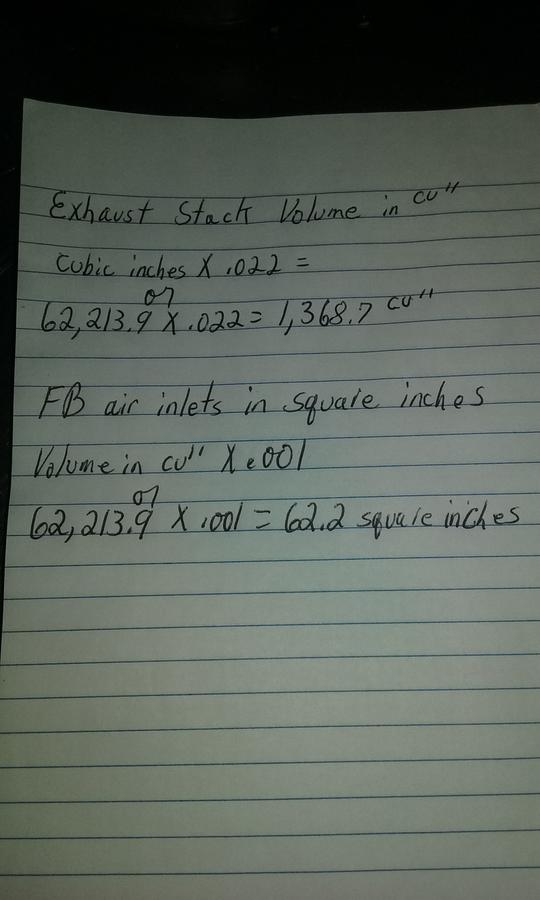

Here is the rest of my numbers. Have only been able to put one pic up at a time. I am trying to plan as much as I can befor I start cutting so I have every thing in my head. All help or addvice is WELCOMED. I have thick skin so yall can't heart my feelings. THANKS Phillip

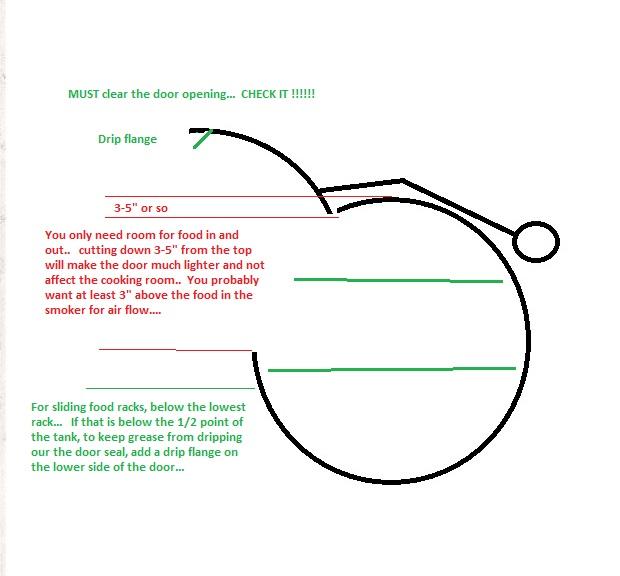

Numbers look good.... Ribwizzard recommends installing the FB before cutting the door.... for the door, here is one thought....

You want the pivot above the door seal so the seal doesn't get in a bind when the door opens.. You can rib the door(if it looks like it will spring).... you want the ribs to fit perfect and only stitch weld them so there's no warping of the door.. leave about 1/16 gap when welding the ribs..

You want the pivot above the door seal so the seal doesn't get in a bind when the door opens.. You can rib the door(if it looks like it will spring).... you want the ribs to fit perfect and only stitch weld them so there's no warping of the door.. leave about 1/16 gap when welding the ribs..

Last edited:

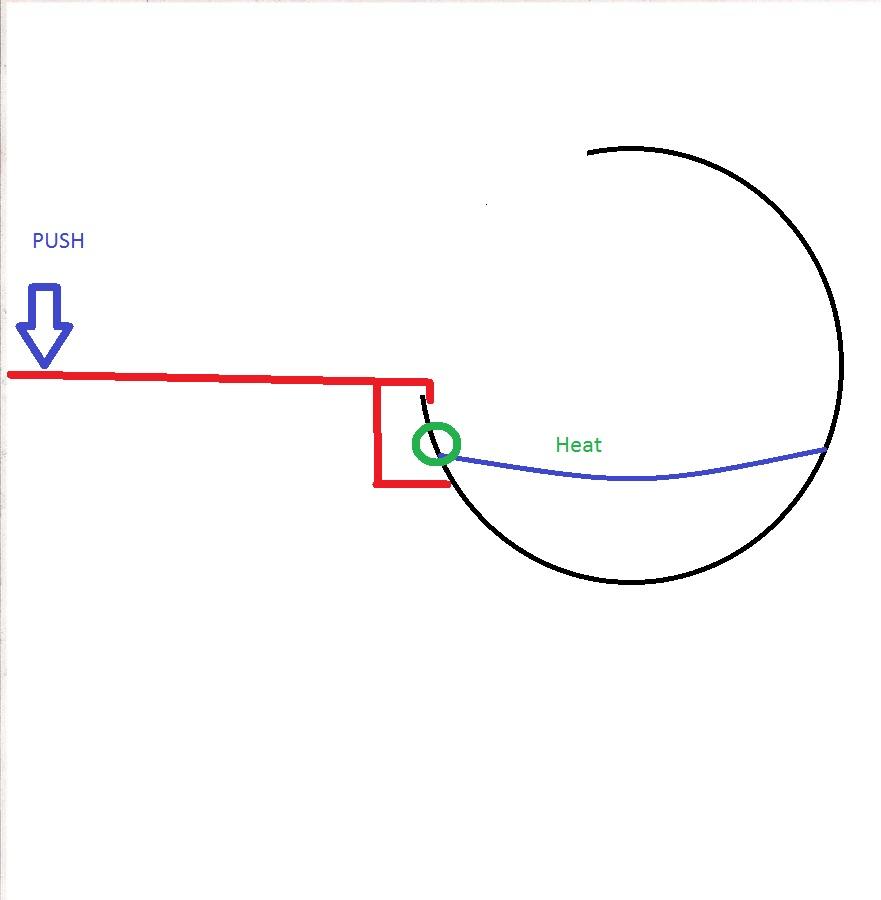

Thanks Dave. The doors are next on my list to plan out. I was thinking I would need the door opening to work on the inside of FB and RF plate.I am trying to figer my hinge desine.I did not have it on paper but I am seeing that the smoke stack needs to be 36" above CC. I am coming up with that I will need a 7"X 36" smoke stack. That just sounds very big or is that right.Also with 1/4" steel do you think I need to reinforce the doors like I'm your pic.So far I am looking to cut my doors 31" long with a 3" gap between the 2 door with 1.5" flat stock around doors.

I don't know if the doors will twist... don't know how to predict that PITA situation... Doesn't happen all that often, I guess, from the posts on here... Probably depends, somewhat, on the tank original build and thickness of the metal.... As far as the door straps go, if I built a propane tank smoker, I would put them on the door to save the headache of straightening the door after the build... Now, the tank can also warp... seen that, so it's 6:1, half dozen the other...... I had pics of tank wall collapse but they're gone... Here's the tool I recommended to one member to try and pull the tank back so it wouldn't leak air into the smoker.... Smokers must be air tight to function properly...

Thanks for all the input. I have never seen a propane tank build with door strips. But I well keep them in mind for my build. This is my very first build and tacking my time to plain and plain. Whan to get eveything down on paper that i can to keep from working on the fly.

I have been hacking apart a few 250 and 500 gallons lately.

I use a plasma cutter to cut the doors and on a 250 Gallo cut 7" (180 mm down from 12 o/clock and 3 " below 3 o'clock.

Stay at least 1 " away from the tank end welds for the vertical cuts.

How I have been doing it is cut out the doors, then weld in the guides before removing the tank end.

I cut the whole end off the tank so we can use the dish for Al Asadors.

Here's the 500 gallon I have been working on.

I use a plasma cutter to cut the doors and on a 250 Gallo cut 7" (180 mm down from 12 o/clock and 3 " below 3 o'clock.

Stay at least 1 " away from the tank end welds for the vertical cuts.

How I have been doing it is cut out the doors, then weld in the guides before removing the tank end.

I cut the whole end off the tank so we can use the dish for Al Asadors.

Here's the 500 gallon I have been working on.

Here's the hinges and door handles I use. The trick is to set the pivot point of the hinge as far back towards 12 o'clock on the tank as possible so they do not bind on the door seal. Also weld the top door seal so it only just covers the gap and there is less over hang to bind.

Ahumadora thanks for the input and feed back. When you were talking able welding in the Guides were you talking about for the slide out racks. I am thinking of notching out the bottom of tank for FB and putting my smoke stack in the end over the FB. The top of the FB I'm planning to be 30x30 square and 24'' deep be for it is put to tank. I am planning to have around 20'' or 22'' X 30 left on top to put a warmer box on top of FB. Every One on here has been great with feed back a input. When I get all my plaining done and all of numbers and measurements down on paper. I well start a New Post when I start work on my smoker/ grill / countertop / wood box / cooler all mounted on a trailer.

I am still at planning my build. I am thinking of a warming box over the FB. Asking if it is worth the time to put one on or a waste of time a money. If i do it will be 19.5"D x 29.5"W ID. 36" or 40" tall.

I have started drawing my build on grafe paper. I have used the calulating form here on SMF. it is telling me for my 250gal tank to put the RF plate 11.5" high. After drawing it out on paper it looks allfull high to me. I am showing my RF to be 3" below 3 o'clock. Guess I am just nervous about my first build but would like some feed back. Every one has been grate so far and love reading about others build.

Phillip.

Phillip.

Phillip.

I also have that problem also when doing the calculations. Although Daves measurements work great they have practical limitations.

I make 3 levels of grates in my smokers for extra capacity so need the RF plate as low as posible.

What I do is pick a number half way between Feldons and Dave's for the FB/CC chamber hole size.

Then put a good V in the RF plate to lower it in the center even more.

Works great and have perfect temps end to end.

Use the throat calculator here http://planetcalc.com/search/?tag=3128 to do the math.

I also have that problem also when doing the calculations. Although Daves measurements work great they have practical limitations.

I make 3 levels of grates in my smokers for extra capacity so need the RF plate as low as posible.

What I do is pick a number half way between Feldons and Dave's for the FB/CC chamber hole size.

Then put a good V in the RF plate to lower it in the center even more.

Works great and have perfect temps end to end.

Use the throat calculator here http://planetcalc.com/search/?tag=3128 to do the math.

One more questions guys.I am thinking on my chimney of just cutting a hole in the top of my tank above the FB then weld it in/up. But I have seen were some guys cut a hole in the side of tank and build a manifold to put the chimney on top. Is there a difference or not.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 4

- Views

- 376

- Replies

- 230

- Views

- 13K

- Replies

- 3

- Views

- 261

- Replies

- 3

- Views

- 1K

- Replies

- 35

- Views

- 1K

Hot Threads

-

Questions for RecTeq owners

- Started by schlotz

- Replies: 66

- Blowing Smoke Around the Smoker.

-

Spammer PMs, Anybody Else?

- Started by chilerelleno

- Replies: 65

- Blowing Smoke Around the Smoker.

-

Lost my dad yesterday

- Started by normanaj

- Replies: 40

- Blowing Smoke Around the Smoker.

-

On the Edge of Trying Sausage Making

- Started by BrianGSDTexoma

- Replies: 35

- Sausage

-

Took a stroll this afternoon

- Started by Buckeyedude

- Replies: 33

- Field and Stream