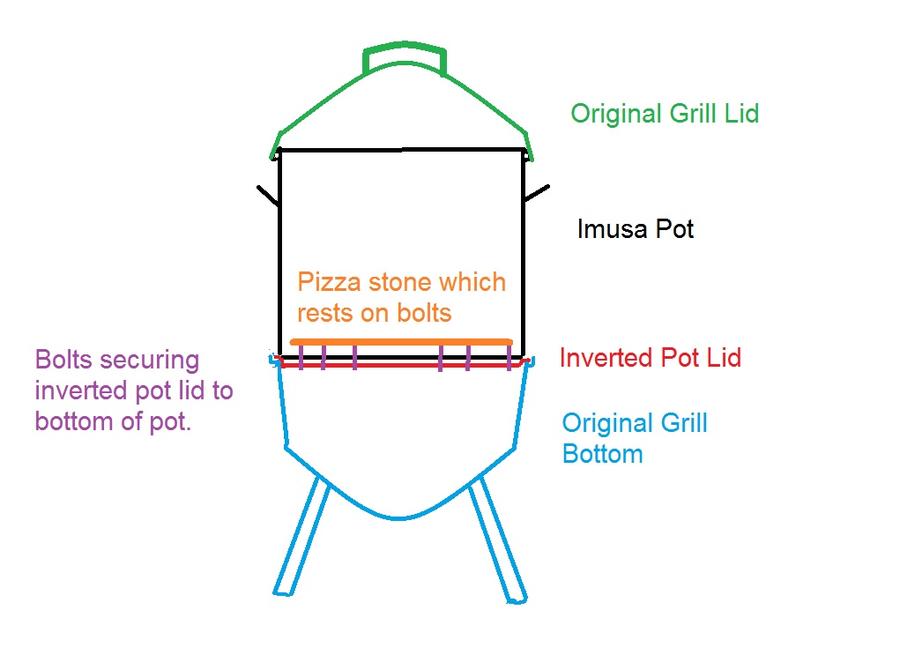

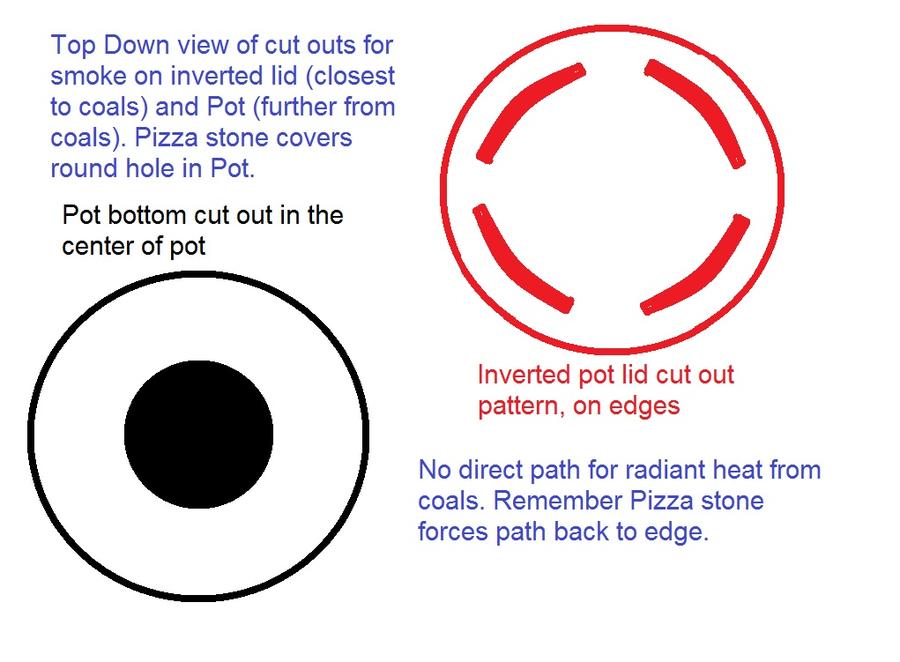

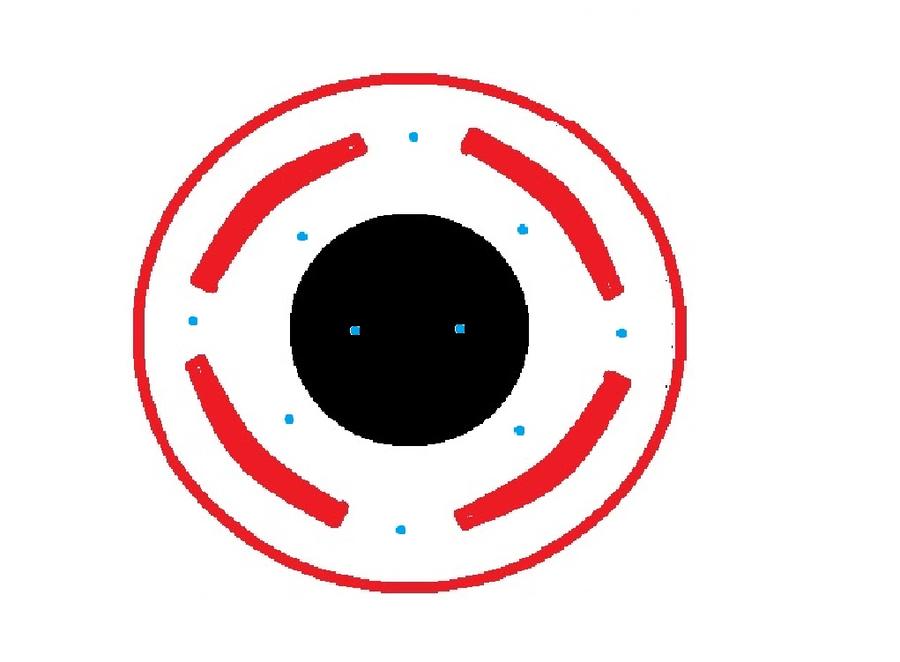

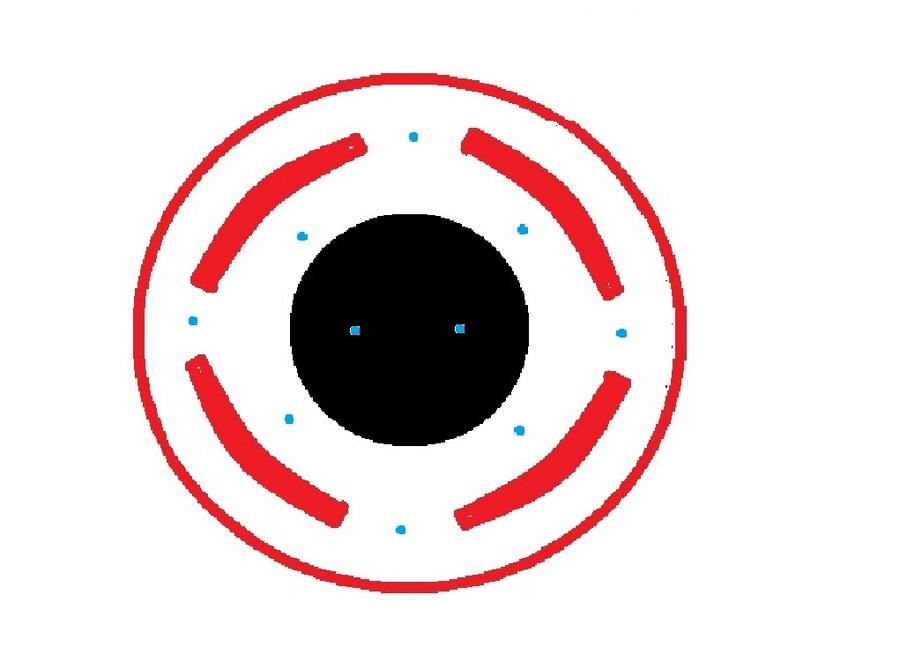

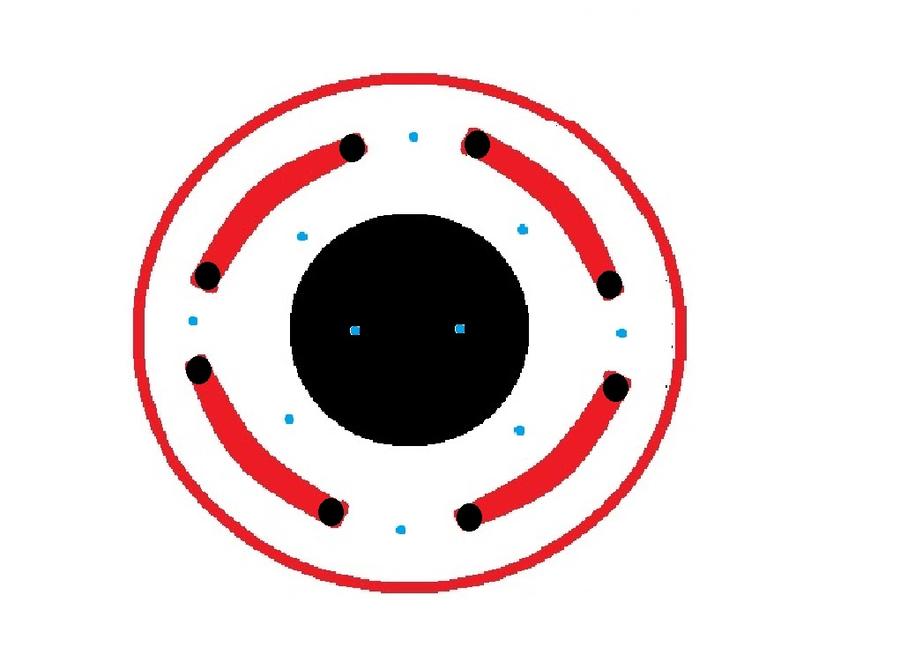

I looked at my sad Cuisinart portable kettle sitting ignored on the porch. With other grill and smoker purchases recently, it has seen no use. I am going to use it as the core of a "mini WSM"-like smoker. It is just a little bit smaller than the smoky joe, so some modifications of the standard build will have to be performed. The inverted pot lid fits snugly on the base (very airtight), but the smoker lid walks all over the top of the standard pot because the pot lip is too big by a quarter inch. I will have to remove about half of the lip on the top of the pot for the smoker lid to fit. I plan on moving the lid latches from the base of the unit, to the pot. This way, I can use the handle on the top to lift everything but the base to the kitchen to get the meat out. Pictures will be posted as each stage of the mod are completed. More postings later.

Last edited: