So, I obtained an old refrigerator last summer with the intent on using it as a dry curing chamber for meats. It did not survive the move on the trailer to the house and I had to junk it.

Well, today I scored a better one. It's a commercial grade laboratory frig. that was used to house water samples. No pathogens or chemicals. It is about 3 ft. wide. 2ft. deep and 6 ft. high. Has double glass doors.

It needs a good cleaning and sanitizing with vinegar, but otherwise it is in great shape!

So, being new to dry curing meats I have a few questions:

Are the glass doors detrimental to the quality of the final product? Does the curing chamber need to be dark? Answered

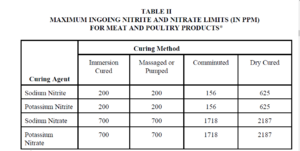

What is the recommended ppm of cure #2 for dry cured meats? How much per pound or Kg? Answered

How much salt is recommended for dry cured meats? What percentage? Answered

What controllers does the brain trust here @SMF recommend for the temp. and humidity?

What humidifiers, fans, heater, other equipment do you recommend?

And finally, what do you recommend I make first as a beginner?

Well, today I scored a better one. It's a commercial grade laboratory frig. that was used to house water samples. No pathogens or chemicals. It is about 3 ft. wide. 2ft. deep and 6 ft. high. Has double glass doors.

It needs a good cleaning and sanitizing with vinegar, but otherwise it is in great shape!

So, being new to dry curing meats I have a few questions:

Are the glass doors detrimental to the quality of the final product? Does the curing chamber need to be dark? Answered

What is the recommended ppm of cure #2 for dry cured meats? How much per pound or Kg? Answered

How much salt is recommended for dry cured meats? What percentage? Answered

What controllers does the brain trust here @SMF recommend for the temp. and humidity?

What humidifiers, fans, heater, other equipment do you recommend?

And finally, what do you recommend I make first as a beginner?

Last edited: