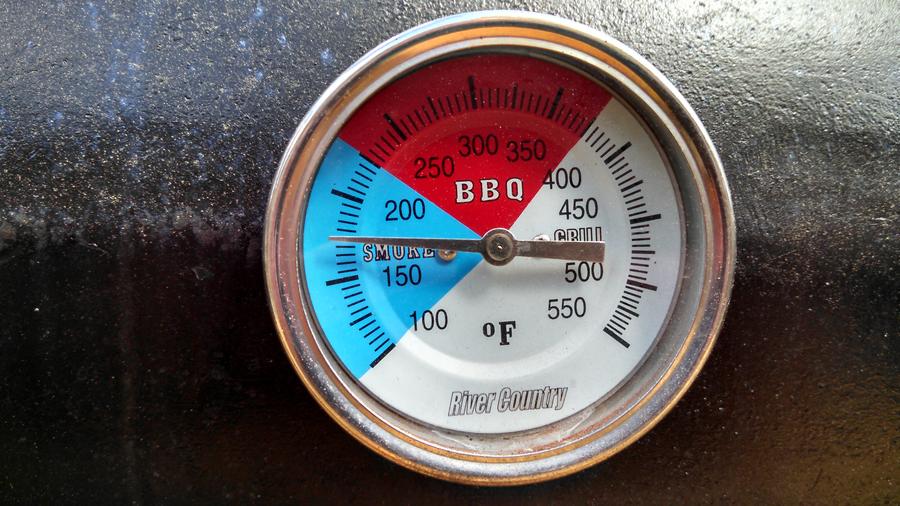

I am starting a new build, I have the bug after my first budget build. So hopefully I can get a little more input on this one than the last. It was still a blast and produces some good eats.

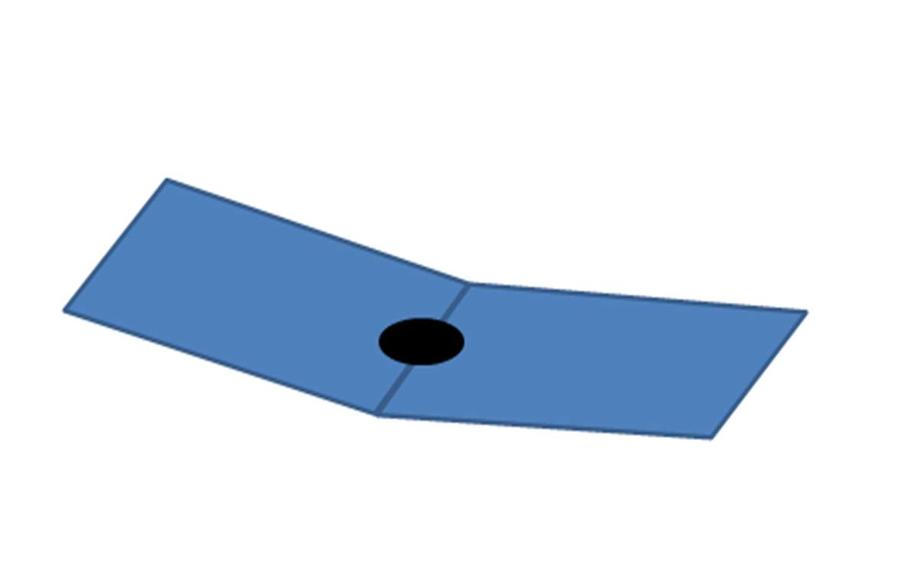

My idea is i want a center feed RF. I have seen the ones where the CC sits directly on top of the FB. I want to have a detached FB and pipe into the CC.

What i am working with is an old 36x60 kerosene tank, a 16ft boat trailer and a FB that i will have built.

I made up a rough sketch with some calculations that I used from feldons and Dave Omaks thread. I am not that confident in my mathematics so i just want to be sure and see if anyone may have some suggestions on the build. So if yall could take a look at the sketch and give some feedback that would be awesome!

Thanks in advance!

My idea is i want a center feed RF. I have seen the ones where the CC sits directly on top of the FB. I want to have a detached FB and pipe into the CC.

What i am working with is an old 36x60 kerosene tank, a 16ft boat trailer and a FB that i will have built.

I made up a rough sketch with some calculations that I used from feldons and Dave Omaks thread. I am not that confident in my mathematics so i just want to be sure and see if anyone may have some suggestions on the build. So if yall could take a look at the sketch and give some feedback that would be awesome!

Thanks in advance!

![20150809_074930[1].jpg](/media/20150809_074930-1-jpg.417156/full?d=1507236367)

![20150809_074939[1].jpg](/media/20150809_074939-1-jpg.417157/full?d=1507236367)

![20150809_074954[1].jpg](/media/20150809_074954-1-jpg.417158/full?d=1507236367)