IPBG,

Treat the propane tank like you would a girl.

Give it the sniff test before you go in!!

Poke your nose in the opening and if there is a strong odor of gas do the water/dish wash if none, hit it!

For most newbies reading this forum who are building at home I would recommend using a grinder with cutoff wheel to do the door cut outs. (most tanks are max 1/4")

you should be able to score a 9" or 7" grinder cheap in the USA and use a few cutoff discs. (9" grinders are for men, so give them the respect they deserve, I have smashed some of my teeth when they have kicked back!)

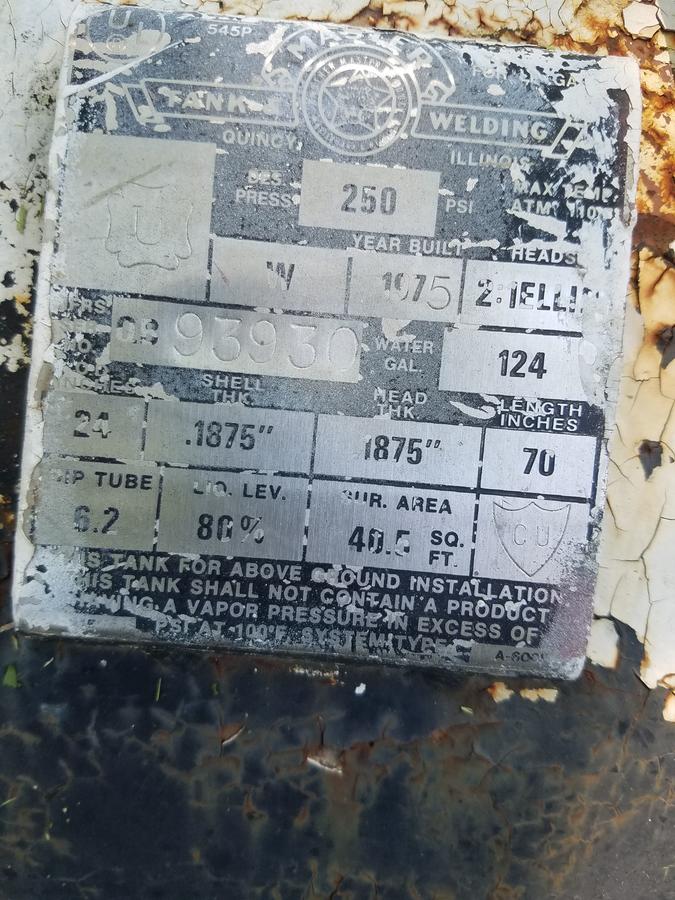

For a nasty old tank like you have above use a wire wheel on the grinder. ( much easier to do the entire tank now BEFORE you cut into it to clean it up.)

Then use a flexible steel ruler to measure down from 12 o'clock. For a tank that diameter I would probably make the top cut about 6" (150mm) down from 12 o'clock. bottom cut about 3" below 3 o'clock. You can wrap a tape around the circumference to divide it into quarters.

Mark it with a scribe or fine tip marker ( don't use a melted old crayon or blunt marker pen.) For the sides of the door stay about 1 1/2' (35mm away from the weld so as not to hit the internal ring.

If you have a plasma cutter you can use that if you have a new electrode. Don't use a gas torch to cut out the doors, that's just hack! I don't care how good you are with a gas torch, you can't come close to the presicion of a cutting wheel. Take you time and make everything perfectly straight and square.

To block all the openings on the top cut the minimum posible to remove the threaded bung. It is much easier to cut square holes and filll them. You can use 3/16 or 1/4" plate to fill them. Tack weld one side in then tap it down until it is flush and work your way across to the other side. You can tack weld on a piece of scrap to the tab to stop it falling in, then cut it off after.

As I said before.

Post it here and the kind folk here can help you with it. 20 mins on the computer beats grinding off a F%$&^ up door or firebox.