Well,

I am finally starting my first build. It seems like it was never going to happen. First I did not have much free time, and two I was nervous about making mistakes. I still don't have much free time, but I am completely over making mistakes partially due to already making over a dozen of them. I want to thank DaveOmak for helping me with the calculations. I read through several threads and learned so much from Dave and others listing a great deal of advise to others who were starting their first builds. This is a great site to learn from. I look forward to making future posts. I am definitely not a professional welder, and my family would probably go hungry if this was my profession, but I greatly enjoy this. This is my first, but definitely not my last. I am building this for my employer. I love to cook, and want to use this to cook for customers, employees and maybe start some competitions.

I specialize is designing concrete mix designs and testing construction materials so I have a few surprises that involves concrete towards the end of the build. My plan is to have this mounted on a trailer. I am limited on tools, but I do have a stick welder and an acetylene torch. My wish list involves a mig welder and a plasma cutter.

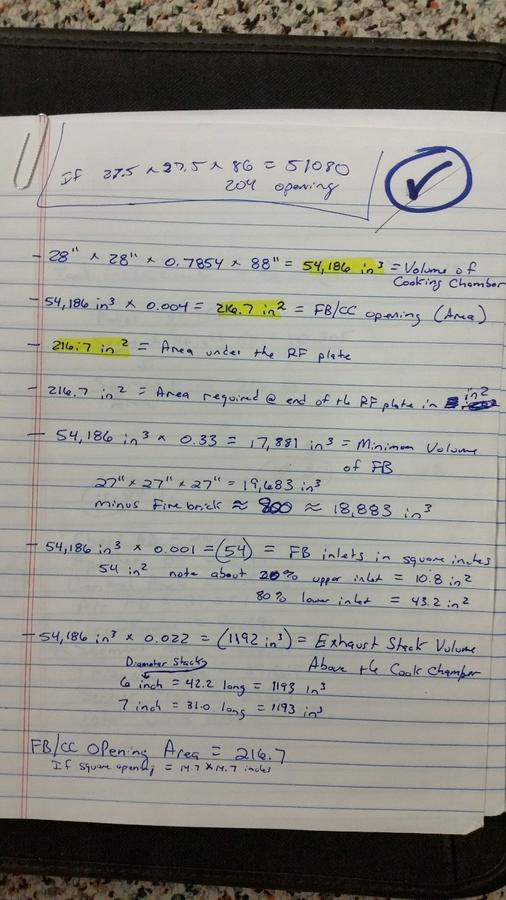

My calculations were as follows (again, thanks Dave):

I purchased an old tank from a propane store. I noticed they had a few rusting in the back and went in and was able to purchase for $40. I brought it back to the shop and filled it with soap just to be safe.

The top was in somewhat bad shape, so I decided to make the top of the propane tank the bottom of my cooking chamber and once filled with water, I cut out the opening for the firebox. At the time, I was unsure of the opening size I needed so I made sure I cut it too small. Just wanted to cut it open for now.

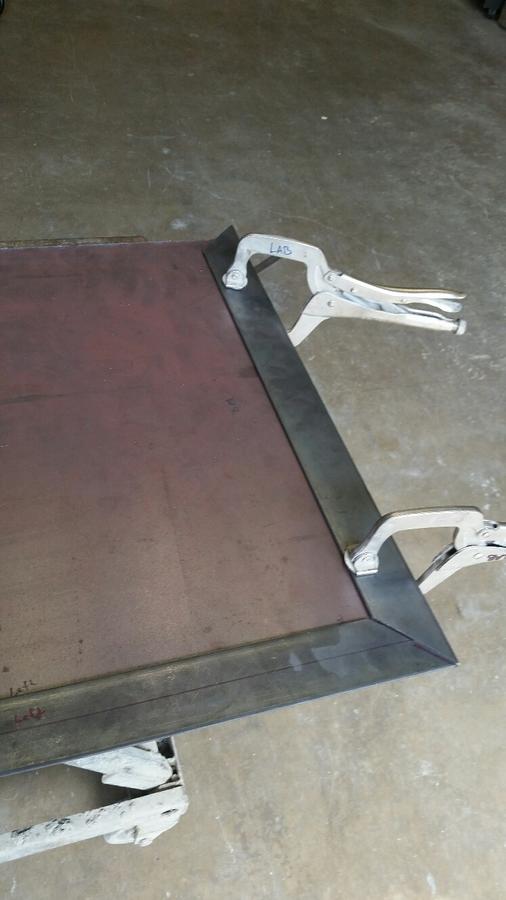

I bought some 1/4" thick hot rolled steel plates and cut them 27" x 27" for my fire box. I wanted to work on the fire box first before I started cutting out the doors on the tank. I have learned that welding on the fire box to the cooking chamber (cc) could create movement from the heat and weight and could have problems getting the doors to fit correctly. So, the fire box (fb) is where I focused my time from here.

A friend of a friend had a plasma cutter, so before the fb was welded together, I had the door cut out. I now want one

Then I welded a few pieces of angle iron inside for the fire basket

I also got to give a shout out to Brian & Rod. They are helping me and have spent a great deal of time grinding out all of my ugly welds.

Also worked on the FB door

Welded on the hinges. I made a big mistake here. I should have reinforced the inside of the door before welding this and I should have not welded the entire hinge at once. The door warped and does not close all the way.

Before welding on the door, I added a strip piece on the inside where the door connects to the hinges to help prevent smoke escaping the firebox

Now to fix the door. I manueverd the FB so the door was on top, heated it up with a torch, and placed some weights on top. Left it over night. It helped some, but there is still a little outward bow to the door. Any suggestions?

I started cutting out my vents. I wanted the vents to be on the side of the smoker and placed where they would be under the fire. I may install a vent on the fir box door if needed but I have seen several functioning smokers without the door vent. If I do install a vent on the smoker door, it will be above the fire level. Any suggestions would be appreciated. I also torched out the FB opening to the CC.

Intentionally waiting to weld on the handles for the vents until I am done having to move it around. I am planning to install handles using welding hammers and will probably attach once the FB is attached to the CC.

I got my tank inside and I am ready to finish my cut out, and that is when I realized I made another mistake. Well maybe a mistake. The doors on the CC will be on the main factory weld on the tank. I can cut out the doors on the other side, but it will be somewhat arkward becuase of the direction the FB door opens.

Will this be a problem? Has anyone ever cut the CC doors through the main weld? I am planning on cutting out two separate doors.

Pic above shows the factory weld on the tank. Since I decided to make the top of the tank the bottom, I am now dealing with this potential problem.

This is my current status as of now, but will work on this every chance I get. Thanks in advance to anyone who can help me with any suggestions.

I am finally starting my first build. It seems like it was never going to happen. First I did not have much free time, and two I was nervous about making mistakes. I still don't have much free time, but I am completely over making mistakes partially due to already making over a dozen of them. I want to thank DaveOmak for helping me with the calculations. I read through several threads and learned so much from Dave and others listing a great deal of advise to others who were starting their first builds. This is a great site to learn from. I look forward to making future posts. I am definitely not a professional welder, and my family would probably go hungry if this was my profession, but I greatly enjoy this. This is my first, but definitely not my last. I am building this for my employer. I love to cook, and want to use this to cook for customers, employees and maybe start some competitions.

I specialize is designing concrete mix designs and testing construction materials so I have a few surprises that involves concrete towards the end of the build. My plan is to have this mounted on a trailer. I am limited on tools, but I do have a stick welder and an acetylene torch. My wish list involves a mig welder and a plasma cutter.

My calculations were as follows (again, thanks Dave):

I purchased an old tank from a propane store. I noticed they had a few rusting in the back and went in and was able to purchase for $40. I brought it back to the shop and filled it with soap just to be safe.

The top was in somewhat bad shape, so I decided to make the top of the propane tank the bottom of my cooking chamber and once filled with water, I cut out the opening for the firebox. At the time, I was unsure of the opening size I needed so I made sure I cut it too small. Just wanted to cut it open for now.

I bought some 1/4" thick hot rolled steel plates and cut them 27" x 27" for my fire box. I wanted to work on the fire box first before I started cutting out the doors on the tank. I have learned that welding on the fire box to the cooking chamber (cc) could create movement from the heat and weight and could have problems getting the doors to fit correctly. So, the fire box (fb) is where I focused my time from here.

A friend of a friend had a plasma cutter, so before the fb was welded together, I had the door cut out. I now want one

Then I welded a few pieces of angle iron inside for the fire basket

I also got to give a shout out to Brian & Rod. They are helping me and have spent a great deal of time grinding out all of my ugly welds.

Also worked on the FB door

Welded on the hinges. I made a big mistake here. I should have reinforced the inside of the door before welding this and I should have not welded the entire hinge at once. The door warped and does not close all the way.

Before welding on the door, I added a strip piece on the inside where the door connects to the hinges to help prevent smoke escaping the firebox

Now to fix the door. I manueverd the FB so the door was on top, heated it up with a torch, and placed some weights on top. Left it over night. It helped some, but there is still a little outward bow to the door. Any suggestions?

I started cutting out my vents. I wanted the vents to be on the side of the smoker and placed where they would be under the fire. I may install a vent on the fir box door if needed but I have seen several functioning smokers without the door vent. If I do install a vent on the smoker door, it will be above the fire level. Any suggestions would be appreciated. I also torched out the FB opening to the CC.

Intentionally waiting to weld on the handles for the vents until I am done having to move it around. I am planning to install handles using welding hammers and will probably attach once the FB is attached to the CC.

I got my tank inside and I am ready to finish my cut out, and that is when I realized I made another mistake. Well maybe a mistake. The doors on the CC will be on the main factory weld on the tank. I can cut out the doors on the other side, but it will be somewhat arkward becuase of the direction the FB door opens.

Will this be a problem? Has anyone ever cut the CC doors through the main weld? I am planning on cutting out two separate doors.

Pic above shows the factory weld on the tank. Since I decided to make the top of the tank the bottom, I am now dealing with this potential problem.

This is my current status as of now, but will work on this every chance I get. Thanks in advance to anyone who can help me with any suggestions.

Last edited: