- Oct 15, 2015

- 19

- 10

Hello,

I've mentioned this smoker and posted a few pics of it, but I haven't given a full-on description and detailing yet.

I built it for a buddy of mine who is on a BBQ team here in Memphis. He assisted me in doing the grunt work, grinding, chipping, cutting with the saw, etc. I did all the welding, torch cutting, fitting, planning, etc.

It is not finished yet, but it is cooking. We began on 8/29, and had it in a competition on 10/3. We literally worked until 1:30am the night prior to his meat check in. He placed 3rd in chicken out of 40 or so. Ribs, not so well, but they were good to me.

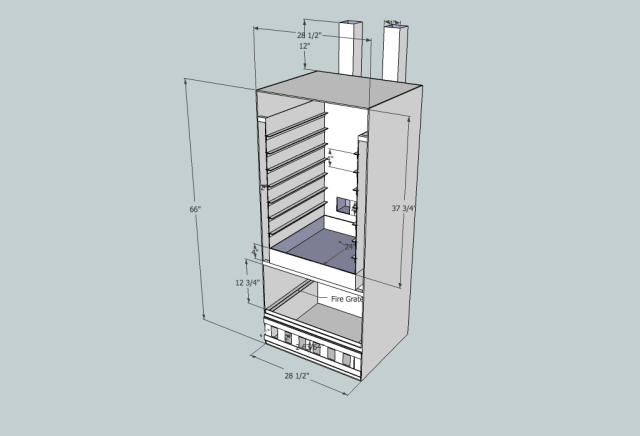

When we started talking about it, I told him to find or sketch a design he liked, and he found this online.

It is a vertical smoker with false walls. The smoke is supposed to travel up btwn the false wall and outer wall, then down into the cook chamber, then out of the low mounted stacks. I had doubts, but whatever. Lets do it.

I started rounding up material. I figured we'd need a sheet of 3/16" plate to build it out of. I changed the dimensions and material thickness on this design to save $, weight, and waste as little material as possible. I cut it down from 66" tall to 60", and I ordered a piece plate 3/16"x5'x12'. 3/16" plat is 7.66 lbs per sq ft. That sheet alone weighed 459.6 lbs, and I had use for nearly every shred of it.

Right away, I told him we need to mount it to a trailer, because we are looking at a 600 lbs beast once it's finished. He agreed. So I started planning that out, too.

I work int he steel business, but only had a tiny 80 amp stick welder at home... That wasn't going to cut it. The welders I use at work take entirely too much juice to be plugged into my house, so I wasn't borrowing one. This may come as a shocker to you guys, but I went straight to HARBOR FREIGHT and bought the 170 amp MIG/Fluxcore welder for $184.99. That's anther topic. Just know, I'm very experienced as a welder, and I am totally pleased with my purchase, and it's performance.

So I rounded up some scrap at work...

And we built the trailer.

It's HSS3"x2"x1/4", (HSS stands for "hollow structural steel", or tube steel".

Then I had my shop cut and bend the plate for the smoker.

Then he took off like a rocket from there.

These are my "Throttle Body" exhaust dampers. They work good, and look neato, but do not 100% shut off the flow... alterations are in the works.

We are taking a break for a month or so, and picking up again in November. It wore us out pretty good.

The trailer is very well balanced, having only about 100lbs of tongue weight. We intend to add tables and storage space on the trailer, so that is subject to change.

The stacks are 4" pipe, dual.

The air vents, I recently learned, need to be lowered, so i have an idea to duct the air down under the fire grate with tubing. Opinions would be great on that...

My buddy plans on mounting a fan to feed air fire when it's activated by the thermostat, which is pretty pricey. It is not here yet, so she's naturally aspirated for now.

Tell me what you think, please. I need some good constructive criticism.

Thanks for looking.

I've mentioned this smoker and posted a few pics of it, but I haven't given a full-on description and detailing yet.

I built it for a buddy of mine who is on a BBQ team here in Memphis. He assisted me in doing the grunt work, grinding, chipping, cutting with the saw, etc. I did all the welding, torch cutting, fitting, planning, etc.

It is not finished yet, but it is cooking. We began on 8/29, and had it in a competition on 10/3. We literally worked until 1:30am the night prior to his meat check in. He placed 3rd in chicken out of 40 or so. Ribs, not so well, but they were good to me.

When we started talking about it, I told him to find or sketch a design he liked, and he found this online.

It is a vertical smoker with false walls. The smoke is supposed to travel up btwn the false wall and outer wall, then down into the cook chamber, then out of the low mounted stacks. I had doubts, but whatever. Lets do it.

I started rounding up material. I figured we'd need a sheet of 3/16" plate to build it out of. I changed the dimensions and material thickness on this design to save $, weight, and waste as little material as possible. I cut it down from 66" tall to 60", and I ordered a piece plate 3/16"x5'x12'. 3/16" plat is 7.66 lbs per sq ft. That sheet alone weighed 459.6 lbs, and I had use for nearly every shred of it.

Right away, I told him we need to mount it to a trailer, because we are looking at a 600 lbs beast once it's finished. He agreed. So I started planning that out, too.

I work int he steel business, but only had a tiny 80 amp stick welder at home... That wasn't going to cut it. The welders I use at work take entirely too much juice to be plugged into my house, so I wasn't borrowing one. This may come as a shocker to you guys, but I went straight to HARBOR FREIGHT and bought the 170 amp MIG/Fluxcore welder for $184.99. That's anther topic. Just know, I'm very experienced as a welder, and I am totally pleased with my purchase, and it's performance.

So I rounded up some scrap at work...

And we built the trailer.

It's HSS3"x2"x1/4", (HSS stands for "hollow structural steel", or tube steel".

Then I had my shop cut and bend the plate for the smoker.

Then he took off like a rocket from there.

These are my "Throttle Body" exhaust dampers. They work good, and look neato, but do not 100% shut off the flow... alterations are in the works.

We are taking a break for a month or so, and picking up again in November. It wore us out pretty good.

The trailer is very well balanced, having only about 100lbs of tongue weight. We intend to add tables and storage space on the trailer, so that is subject to change.

The stacks are 4" pipe, dual.

The air vents, I recently learned, need to be lowered, so i have an idea to duct the air down under the fire grate with tubing. Opinions would be great on that...

My buddy plans on mounting a fan to feed air fire when it's activated by the thermostat, which is pretty pricey. It is not here yet, so she's naturally aspirated for now.

Tell me what you think, please. I need some good constructive criticism.

Thanks for looking.