Mike rainwater

Newbie

- Jun 3, 2018

- 18

- 1

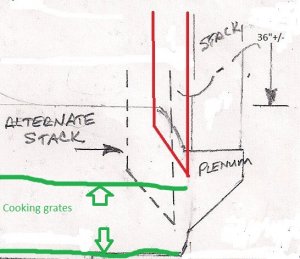

Greetings, I'm building a smaller R V with your suggested ratios. The propane tank is approx. 14 wide by 40 long. You made the recommended FB to CC mounting height to be 1/3. About how far in would you recommend cutting back from the end? I'm a first time newbie. I appreciate any suggestions. Your info has already answered a lot of questions. Thanks so much.Thanks, Ive always used an unwritten formula something like;

CC shape should be like width should be about .35 length

Fire box width= CC width

Firebox height= CC width

Firebox depth= 4/5 CC width

Firebox to CC mounting height 1/3 CC.

And of course stack as mentioned above. Works good for me and sometimes I'll compare it to feldons if its a new size cooker just to see if im close.

Bigger cookers ill downsize the firebox some, and real small ones ill go bigger.

Mike in B-ham