- Aug 7, 2015

- 14

- 11

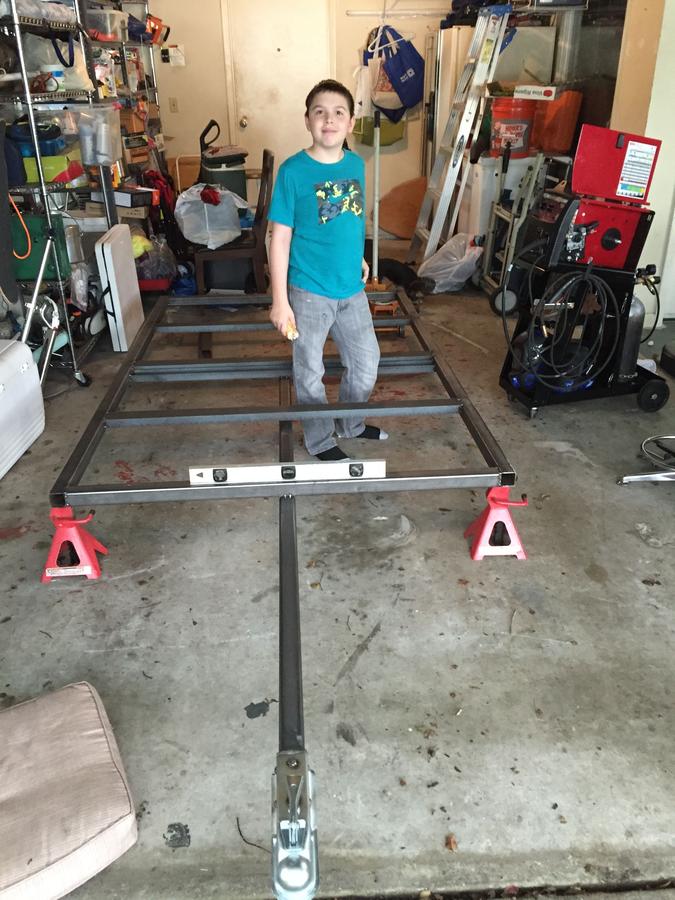

Greetings everyone...I have been browsing this website all year looking for ideas and I'm hooked! When I say that I started from scratch, I REALLY had to work from the ground up. I had never even touched a welder (nor did I know anyone that had one)…so, I took a welding class at a local vocational school here in Tampa. A few months ago, I came across what I believe to be a 250 gallon propane tank. It was a bit rough, but nothing that a few weeks with a wire brush on a grinder couldn’t fix (not fun!). My children and I began fabricating the trailer out of steel tubing. Once the axle and tires were installed, we made the small uprights to cradle the tank on the trailer. We managed to get the tank on the trailer using a “questionable” series of pulleys and ropes attached to the oak tree in my front yard, with the other end on my wife’s truck. At this point, the tank is just sitting on the trailer and I have outlined where I want the doors to go. I am a little nervous about cutting into the tank due to concerns that other posters have mentioned involving warping of the doors and tank. I am renting a plasma cutter this week and would like to get all of the heavy cutting (tank doors, firebox cut-out and the six pieces for the firebox) done on the same day (to save $). I was able to get two full sheets of 1/4” steel at the scrap yard and should be good to go once I get the surface rust brushed off.

I am a little nervous and want to proceed cautiously…so…I wanted to ask everyone the following questions:

Here are some photos of my progress...I would love some suggestions! Thanks guys!!!

I am a little nervous and want to proceed cautiously…so…I wanted to ask everyone the following questions:

Here are some photos of my progress...I would love some suggestions! Thanks guys!!!

I recently read a post that mentioned that the smoke box should be welded onto the tank before I cut the doors to minimize warping. Is this true?

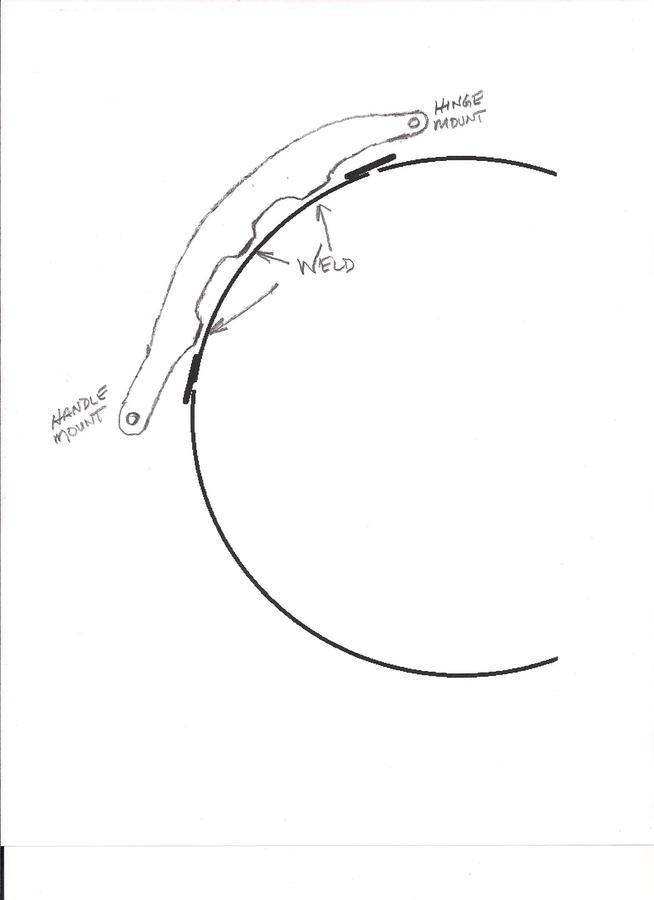

Should I weld steel ribs onto the doors to prevent them from warping and curling outwards?

I was looking at the Feldon’s firebox calculator and was surprised at how big the firebox needed to be! The recommended firebox size for a 250 gallon tank is 19,250 cubic inches. I was planning on using a box size of 25” high x 30” wide” x 26” long (19,500 cubic inches). I had to reduce the height of the box due to my concerns over ground clearance. What is the minimum ground clearance recommended? Also, is 25” high insufficient? (The fire will undoubtedly hit the top of the firebox…but, if I go taller I will probably bottom out if I hit a bump in the road). Recommendations???

I recently purchased some 3” bullet hinges for the fire box and smoker doors. They were pretty inexpensive (2 for $10). Does anyone have any experience with these hinges?