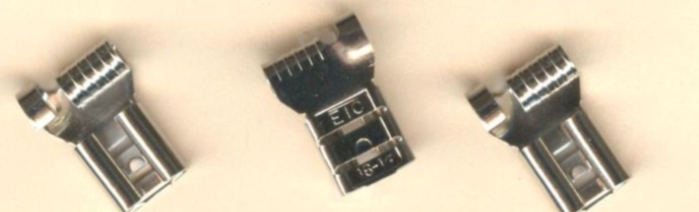

Hey guys! My MES40 hasn't worked in a while and I finally decided to pop off the access panel on the back and take a look. The cap had disintegrate and the wire was no longer connected. Now when I (maybe stupidly?) decided to check what would happen if I touched the wire to the connector it sparks much larger than what I expected. I haven't bought a cap and reconnected yet as I am not sure if there is more long like the element or something else? If anyone has any advice please let me know. Below is a pic of the access!

Thank you in advanced

Thank you in advanced