Smoker frame

- Thread starter senorkevin

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

smokin phil

Smoking Fanatic

- Jun 6, 2012

- 374

- 30

mikeweber83

Newbie

- Apr 30, 2015

- 18

- 13

the most difficult thing would probably be alignment and sealing the thing i would think. a lot of hope drilling too but certainly its possible

smokejumper

Smoking Fanatic

A bolted box section frame is totally do-able.

In some ways, bolting makes it easier to align things, since you are able to loosen joints and readjust things which you can not do with a welded assembly.

There are all kinds of commercial racks, tables, benches, carts, etc. that are bolted as standard operating procedure.

Most of these carry much greater loads than a smoker frame.

In some ways, bolting makes it easier to align things, since you are able to loosen joints and readjust things which you can not do with a welded assembly.

There are all kinds of commercial racks, tables, benches, carts, etc. that are bolted as standard operating procedure.

Most of these carry much greater loads than a smoker frame.

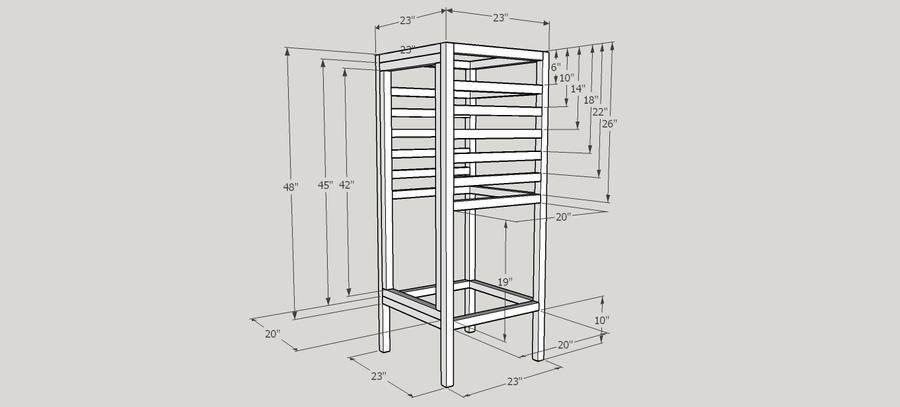

I am planning on using 1.5 inch box and 1/8 grade steel plate. The panels will also be bolted to the frame so is doesn't bow. I might even bolt the shelf supports to the plate. I'll seal it with high temp non toxic silicon or silicon cement. I'll try a post a frame design later.

Here is the plan so far... I might change the rack supports to angle iron and bolt them to the sides of the smoker. Please feel free and add comments suggestions.

hamrhead1971

Smoking Fanatic

This will be an interesting build and I will definitely be watching. The frame absolutely will need to be bolted together. I would consider using self-tapping screws for the outer skin.

I'm not sure about about self tapping screws. However, I was thinking about tapping where possible. Less holes the better!

smokejumper

Smoking Fanatic

Senorkevin,

Consider using Unistrut for the rack mount rails. Or the rest of the frame for that matter. It will allow you to adjust the rack spacing whenever you want. Just make sure to find plain (PL) or stainless unistrut, and avoid the galvanized.

Consider using Unistrut for the rack mount rails. Or the rest of the frame for that matter. It will allow you to adjust the rack spacing whenever you want. Just make sure to find plain (PL) or stainless unistrut, and avoid the galvanized.

That's a sweet idea! Thank you. I'll keep a look out for sure. Don't suppose anyone knows what it is called in Spanish???

Senorkevin,

Consider using Unistrut for the rack mount rails. Or the rest of the frame for that matter. It will allow you to adjust the rack spacing whenever you want. Just make sure to find plain (PL) or stainless unistrut, and avoid the galvanized.

smokejumper

Smoking Fanatic

El unistrut?...Don't suppose anyone knows what it is called in Spanish???

Sorry, gringo humor.

Sometimes, everyone is a comic!!!!El unistrut?

Sorry, gringo humor.

It is called Canel unistrut or unicanal.

Now we can sleep well know what it is called!! (English humor!)

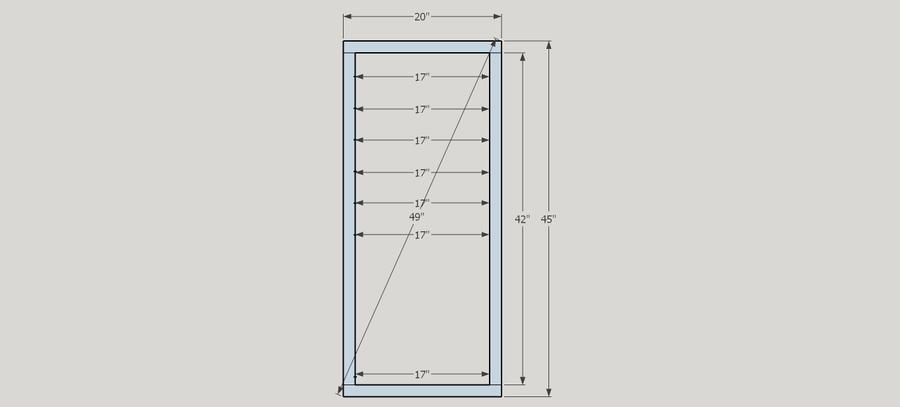

Here is a pic of the door frame. The 17" at the bottom is roughly the heat source (gas burner) level.

The 17" at the very top is the line with I will hang from.

The second 17" from top is the highest rack level.

Where abouts should I drill the holes for the air flow?

I plan on having a slide to open and close.

smokejumper

Smoking Fanatic

smokejumper

Smoking Fanatic

It depends on the design of the smoker.

If you are making a reverse flow cabinet, then the exhaust will be below the food.

If you are making a standard cabinet, the exhaust will be above the food.

In either case, the air intake for the fire should be below the fire if possible.

This might help:

http://www.smokingmeatforums.com/t/174302/vertical-reverse-flow-advice

If you are making a reverse flow cabinet, then the exhaust will be below the food.

If you are making a standard cabinet, the exhaust will be above the food.

In either case, the air intake for the fire should be below the fire if possible.

This might help:

http://www.smokingmeatforums.com/t/174302/vertical-reverse-flow-advice

Here is what I have planned so far. I was planing on welding the bottom plate to the box section. Now however, I think I need to re-design to allow for the air flow. I will be using a propane burner but still want to use charcoal once in a while. I also plan on drilling a hole to allow for cold smoking duct.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 5

- Views

- 473

- Replies

- 0

- Views

- 438

- Replies

- 0

- Views

- 2K

- Replies

- 20

- Views

- 3K

- Replies

- 16

- Views

- 2K

- Replies

- 29

- Views

- 2K

Hot Threads

-

Our Second piece of Heaven, Little piece on the Atlantic Ocean

- Started by DRKsmoking

- Replies: 55

- General Discussion

-

How Do I Get Rid of These Armadillos?!!

- Started by seenred

- Replies: 41

- Blowing Smoke Around the Smoker.

-

Non fat dried milk

- Started by hog warden

- Replies: 37

- Sausage

-

Getting to the bottom of what happens to cure in smoked sausage

- Started by hog warden

- Replies: 31

- Food Safety

-

Featured A couple thick strips please!