- Oct 2, 2014

- 41

- 10

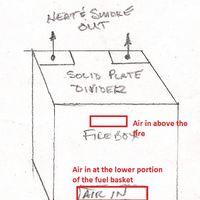

Hi All - Just finished a RF as I was intrigued by all the press and how they smoke with "even" temps. Well just finished and fired for first time. Not real pleased with temps at the moment and could use some advice. I'll post some pics but first let me say I decided to do a mix of wood, tile and metal to lessen the cost as I want to cook large packer cut briskets and store bought ones were too small - just did not work. Custom ones were way beyond my budget but I now know why as it cost me a lot more than I estimated. The Sides are 2x3's lined with tile board and skinned with aluminum. Base of smoker is tile over tile board over steel plate. Side channels to top are aluminum and pic shows where they come out. Top is Tile, over tile board over insulation ~ 3" thick and skinned with Aluminum as well. Fire Pit is 4" block on concrete with a large bbq burner for heat. I have a 4" flue in bottom of box. Box inside is 28" x 4" x 21" . Firs t temp smoke run to test I had 200+ at top and 165 at bottom. That was an hour run with some mesquite. Now that is usable but I plan to do a longer run today as I need 225 and I would like more even temps. My other smokers used a bottom opening and temps were similar but the hot spot was near bottom.

Suggestions - Do O need to close some of the side vents to the top down a bit? Everyone seems to say the only get 5-10 degree variance in the RF box. Thanks

ORSMOKERIN AZ

Suggestions - Do O need to close some of the side vents to the top down a bit? Everyone seems to say the only get 5-10 degree variance in the RF box. Thanks

ORSMOKERIN AZ