Old History Side Fire Box

- Thread starter txsmokedlk

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Not sure why my earier post didn't go through.

Afternoon SMF! WOW these last few months have been BUSY. Got a new job, moved, wife is pregnant with our first child!!!! BOY!!!! County boy moved to city…a whole new world.

So I would like to update and ask what you gentleman and ladies think. I’ve changed a few things…based on availability and cost. My smoker is going to be one of history. The cooking chamber is my dad’s first charcoal grill. Wheels and axle are from my Great Great Grandfather’s old horse drawn plow. I’m working on incorporating some of the old parts in the smoker build. By history I mean Old History!!!

Style of smoker: offset fire box with tuning plates

Cooking Chamber(CC): Can’t change

16 inches Diameter(D) pipe X 26 inches long X ¼ wall thickness(well where it doesn’t have 30+ years of rust), Volume= 5,225 in^3

Fire Box(FB):

16 inches Diameter pipe X 18 inches long X ¼ wall thickness, Volume= 3,619 in^3

Chimney:

Volume needed 181 in^3

Pipe 2.5 in D 37 in long

According to the calculator and reading on the forum I need over 30 in and under 44 in long pipe. I want to mount the pipe at the opposite end of FB, close to level with my cooking surface. I will have about 3 inches of horizontal pipe then a 90 degree turn vertical.

Question: Is the 3 inches of vertical travel included in the overall calculations for the chimney? I’m thinking the 37 inches starts at the vertical turn.

Question: Is the diameter I used in the calculator inside our outside diameter?

Firebox opening to CC: Cut and welded in place.

Area needed 29 in^2. I took the half moon X 2 approach(found from reading lots of posts, you guys are awesome). Then lowered the CC 1.5 in to allow for a grease trap.

Air Intake on FB: Need help

Area needed 11 in^2

Problem: I’m trying to determine the placement of my lower rebar rack that will hold my charcoal box. I’m want two intakes in the bottom door and on at the top of the door. What I don’t know is how large my charcoal/wood burning section should be. If I go on the max side I lose space for my air intakes and the rebar and charcoal box will obstruct the flow of air. How much space do I need for the ash build up.

Have a great day. Dustin.

Afternoon SMF! WOW these last few months have been BUSY. Got a new job, moved, wife is pregnant with our first child!!!! BOY!!!! County boy moved to city…a whole new world.

So I would like to update and ask what you gentleman and ladies think. I’ve changed a few things…based on availability and cost. My smoker is going to be one of history. The cooking chamber is my dad’s first charcoal grill. Wheels and axle are from my Great Great Grandfather’s old horse drawn plow. I’m working on incorporating some of the old parts in the smoker build. By history I mean Old History!!!

Style of smoker: offset fire box with tuning plates

Cooking Chamber(CC): Can’t change

16 inches Diameter(D) pipe X 26 inches long X ¼ wall thickness(well where it doesn’t have 30+ years of rust), Volume= 5,225 in^3

Fire Box(FB):

16 inches Diameter pipe X 18 inches long X ¼ wall thickness, Volume= 3,619 in^3

Chimney:

Volume needed 181 in^3

Pipe 2.5 in D 37 in long

According to the calculator and reading on the forum I need over 30 in and under 44 in long pipe. I want to mount the pipe at the opposite end of FB, close to level with my cooking surface. I will have about 3 inches of horizontal pipe then a 90 degree turn vertical.

Question: Is the 3 inches of vertical travel included in the overall calculations for the chimney? I’m thinking the 37 inches starts at the vertical turn.

Question: Is the diameter I used in the calculator inside our outside diameter?

Firebox opening to CC: Cut and welded in place.

Area needed 29 in^2. I took the half moon X 2 approach(found from reading lots of posts, you guys are awesome). Then lowered the CC 1.5 in to allow for a grease trap.

Air Intake on FB: Need help

Area needed 11 in^2

Problem: I’m trying to determine the placement of my lower rebar rack that will hold my charcoal box. I’m want two intakes in the bottom door and on at the top of the door. What I don’t know is how large my charcoal/wood burning section should be. If I go on the max side I lose space for my air intakes and the rebar and charcoal box will obstruct the flow of air. How much space do I need for the ash build up.

Have a great day. Dustin.

Pics

Inside the FB.

And the future wheels.

Inside the FB.

And the future wheels.

Morning SMF.

It's a amazing what is available in the threads.

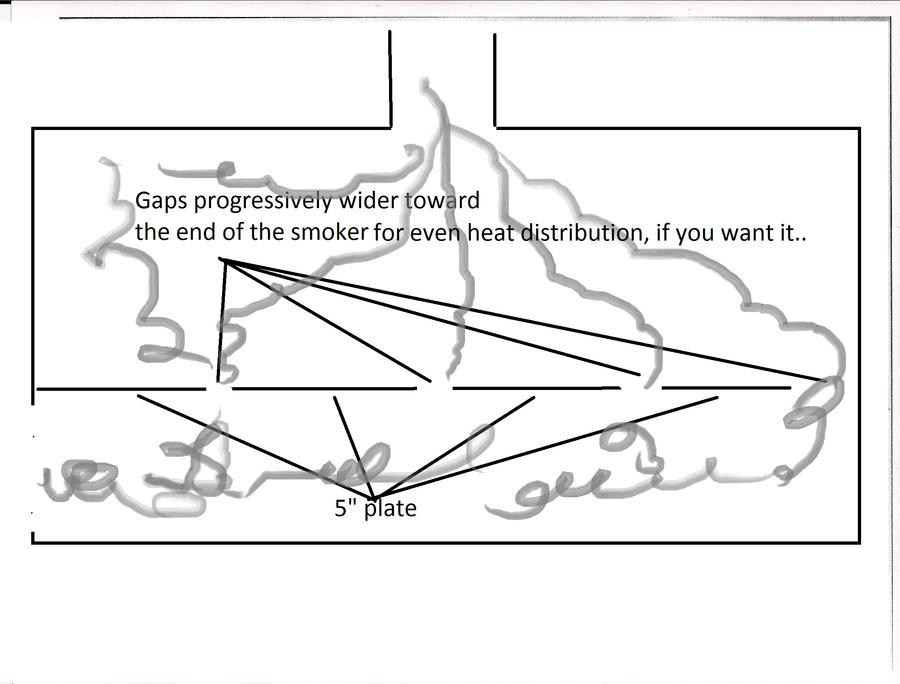

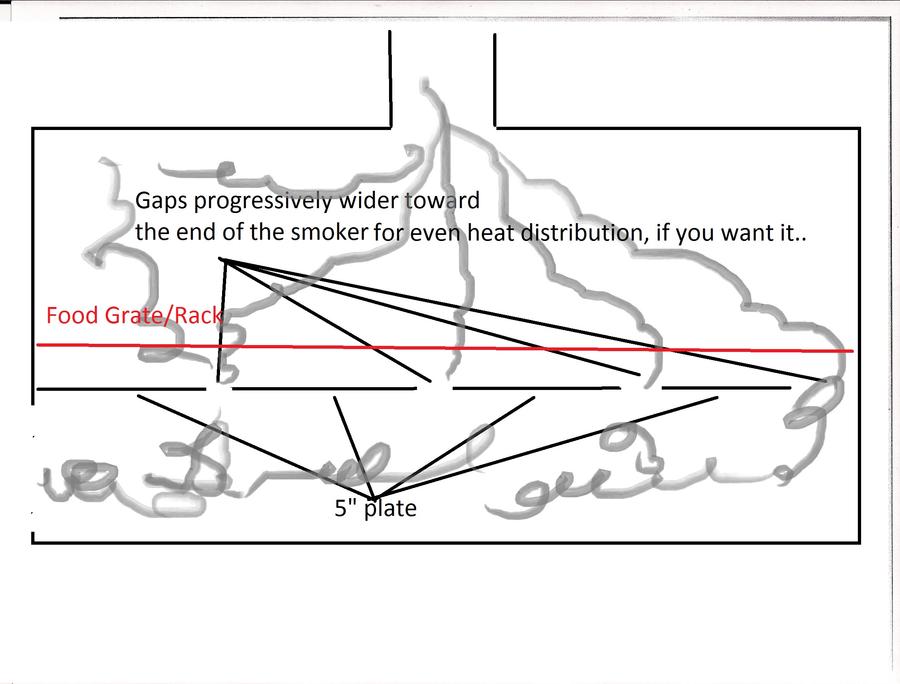

So here's another question. With my CC only being 26 inches long. What would work better baffle like the one Dave posted(pic below), tuning plates, or diflector plate?

Any help would be great.

Thanks

Dustin.

It's a amazing what is available in the threads.

So here's another question. With my CC only being 26 inches long. What would work better baffle like the one Dave posted(pic below), tuning plates, or diflector plate?

Any help would be great.

Thanks

Dustin.

wolfman1955

Master of the Pit

Morning SMF.

It's a amazing what is available in the threads.

So here's another question. With my CC only being 26 inches long. What would work better baffle like the one Dave posted(pic below), tuning plates, or diflector plate?

Any help would be great.

Thanks

Dustin.

I believe the baffle plate you have pictured came from a reverse flow pit Dave was helping a guy with not a SFB like you are talking about. From what I know, witch isn't much, most people go with tunning plates in a SFB.

I've worked on the drawing a little and have an idea for my vents. But I don't know if I'll have enough square inches for the bottom vents. I need about 11in^2 and this configuration will provide 8 on bottom and 4 at top. Any thoughts? Pic below.

wolfman1955

Master of the Pit

I've worked on the drawing a little and have an idea for my vents. But I don't know if I'll have enough square inches for the bottom vents. I need about 11in^2 and this configuration will provide 8 on bottom and 4 at top. Any thoughts? Pic below.

That should work.

Dustin, morning.......

Are you wanting a SFB with tuning plates, or a Reverse Flow with a RF plate ???

Is the exhaust stack already welded into the Cooking Chamber.... If so, does it extend into the CC.....

As the air inlets to the CC go, they should be fine... I have not found anyone that uses or needs them in the full open position.... having the area of the openings split between the upper and lower usually works well....

I'm thinking, with that ID of an exhaust stack, it may be a tad small.... The surface area/volume numbers may have too much friction and loss of air flow... That situation arises in small smokers.... In larger smokers, the reverse is true.... The calculator is a "one size fits all" and some intuitive planning/thinking has to be injected.... Try it knowing the exhaust stack "may" cause some flow restrictions and "may" need to be a larger diameter..... Not saying it will... Just saying....

Are you wanting a SFB with tuning plates, or a Reverse Flow with a RF plate ???

Is the exhaust stack already welded into the Cooking Chamber.... If so, does it extend into the CC.....

As the air inlets to the CC go, they should be fine... I have not found anyone that uses or needs them in the full open position.... having the area of the openings split between the upper and lower usually works well....

I'm thinking, with that ID of an exhaust stack, it may be a tad small.... The surface area/volume numbers may have too much friction and loss of air flow... That situation arises in small smokers.... In larger smokers, the reverse is true.... The calculator is a "one size fits all" and some intuitive planning/thinking has to be injected.... Try it knowing the exhaust stack "may" cause some flow restrictions and "may" need to be a larger diameter..... Not saying it will... Just saying....

Here are 2 designs of stack placement..... These designs work on any design of smoker... If you change the stack placement.....

Last edited:

Thanks Wolfman.

I started taking the plow apart....not easy. My guess is it's at least 100 years old. Bolts are a tad tough to get out to say the least!!!!! Some I'm trying to save and others.....no hope.

I did use a gear and chain lube. The bolts I want to keep I've sprayed once a week for two months and to my surprise they came off nicely. More pics on those later.

I tested a rust remover/dissolver on a few different items to see how it would work. Wow impressive. The rust remover is NOT acidic.

Working pretty good. Eastwood Rust remover.

I started taking the plow apart....not easy. My guess is it's at least 100 years old. Bolts are a tad tough to get out to say the least!!!!! Some I'm trying to save and others.....no hope.

I did use a gear and chain lube. The bolts I want to keep I've sprayed once a week for two months and to my surprise they came off nicely. More pics on those later.

I tested a rust remover/dissolver on a few different items to see how it would work. Wow impressive. The rust remover is NOT acidic.

Working pretty good. Eastwood Rust remover.

Answer in BOLD

Thanks Dave!

Dustin, morning.......

Are you wanting a SFB with tuning plates, or a Reverse Flow with a RF plate ???

(Building a SFB with tuning plates...easier I hope)

Is the exhaust stack already welded into the Cooking Chamber.... If so, does it extend into the CC..... (The stack has been welded in place since 1980...I'm planning on cutting it out and moving it. Does not extend below the weld)

As the air inlets to the CC go, they should be fine... I have not found anyone that uses or needs them in the full open position.... having the area of the openings split between the upper and lower usually works well....

I'm thinking, with that ID of an exhaust stack, it may be a tad small.... The surface area/volume numbers may have too much friction and loss of air flow... That situation arises in small smokers.... In larger smokers, the reverse is true.... The calculator is a "one size fits all" and some intuitive planning/thinking has to be injected.... Try it knowing the exhaust stack "may" cause some flow restrictions and "may" need to be a larger diameter..... Not saying it will... Just saying....(The pipe and it was free, I can try it and if it doesn't work we can try something larger. I'll start looking for larger pipe or square tubing. )

Thanks Dave!

In my opinion, the stack placement will work if you have tuning plates.... The tuning plates should be of 3/16 to 1/4" material... they should fit the width of the Cooking Chamber ABOVE the FB/CC opening... make them about 5" wide.... Placement of plates is totally subjective and a trial and error/preference thing...

....click on pic to enlarge......

....click on pic to enlarge......

Last edited:

Sounds like a good plan Mr Dave. I'll start working on plans for the tuning plates. I want to see if I can drop the plates as low as I can with out restricting air flow. First thoughts are keep enough space below the plates that would equal the FB to CC opening.

But this project is on hold for a few days...Disney here we come!!!!

But this project is on hold for a few days...Disney here we come!!!!

Good Day SMF.

Wow these last few months have been really busy. My wife hit the nesting stage and had me working like a mad man around the house, project after project. My son, Grant was born March 17 and it's been awesome! Hard but awesome.

I did manage to work a little on my smoker. Welded in the baffle.

Worked on the front wheel assembly. It's the old front section of a plow. I removed every piece, wire wheeled with a grinder, and painted.

Wow these last few months have been really busy. My wife hit the nesting stage and had me working like a mad man around the house, project after project. My son, Grant was born March 17 and it's been awesome! Hard but awesome.

I did manage to work a little on my smoker. Welded in the baffle.

Worked on the front wheel assembly. It's the old front section of a plow. I removed every piece, wire wheeled with a grinder, and painted.

And here it is primed.

And now painted with wheels ready go.

I'm still looking for the wood beam that will be the tongue. We have an old tongue with the metal loop(pole cap) on the end. I don't want to cut it but it would be perfect. And I have a single tree. All are in pretty good shape. Just have to preserv the wood.

This is all from my families farm.

And now painted with wheels ready go.

I'm still looking for the wood beam that will be the tongue. We have an old tongue with the metal loop(pole cap) on the end. I don't want to cut it but it would be perfect. And I have a single tree. All are in pretty good shape. Just have to preserv the wood.

This is all from my families farm.

Smoke stack and frame for fire box door are done also. I'm still determining how to install the hinges.

I don't know anything about building a smoker, but I do know a lot about nostalgia and "old" things. I think your idea is wonderful. It really brings back some fond memories. Good luck with the cooker, the new move and especially that great new little one. Joe

Hi Joe.

I was very fortunate, I grew up with my grand and great grand parents. I really hope this smoker works and looks like I hope it will. And to pass it on to my son one day.

One should never forget where they come from.

I was very fortunate, I grew up with my grand and great grand parents. I really hope this smoker works and looks like I hope it will. And to pass it on to my son one day.

One should never forget where they come from.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 8

- Views

- 763

- Replies

- 2

- Views

- 338

- Replies

- 31

- Views

- 3K

- Replies

- 5

- Views

- 476

- Replies

- 12

- Views

- 817

Hot Threads

-

Our Second piece of Heaven, Little piece on the Atlantic Ocean

- Started by DRKsmoking

- Replies: 57

- General Discussion

-

How Do I Get Rid of These Armadillos?!!

- Started by seenred

- Replies: 42

- Blowing Smoke Around the Smoker.

-

Non fat dried milk

- Started by hog warden

- Replies: 37

- Sausage

-

Featured A couple thick strips please!

-

Getting to the bottom of what happens to cure in smoked sausage

- Started by hog warden

- Replies: 31

- Food Safety