Im a little confused about the adjustments that need to be made to feltons calculator. Here are my specs.

[url=http://feldoncentral.com/bbqcalculator.html?cc=0,0,200,0,0,0,46200.00,15400.00&fb=25.5,25.5,25.5,0,0,16581.38,15400.00,107.7&ch=6,829.07,29.34&fi=0,0,0,49.74,0&fc=13.00,18.38,132.65]Link to BBQ Pit Calculator[/url]

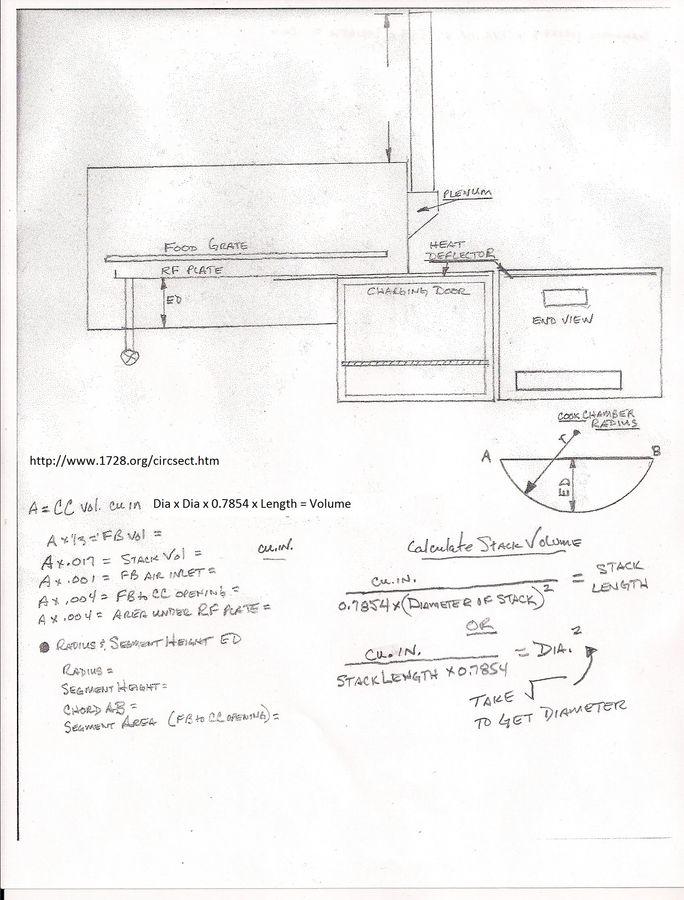

I think I need to make the firebox to cc opening 1.5x the measurement in the calculator. Is that correct?

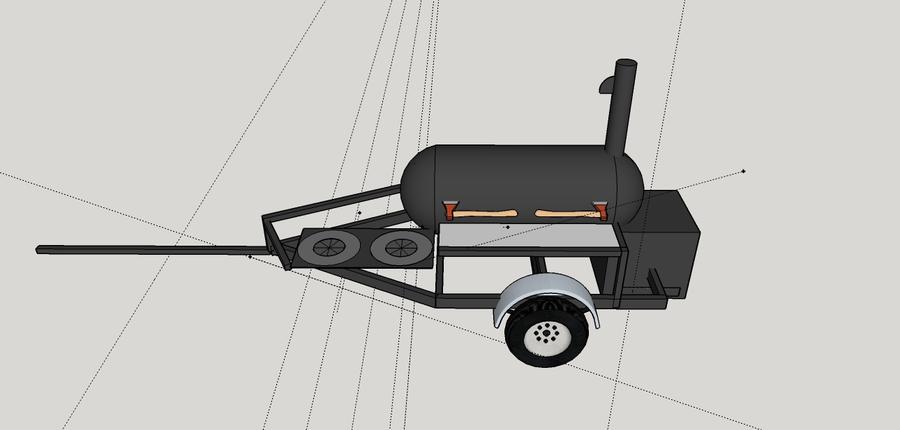

Also is the vent stack ok at just under 30in?

I really have no idea what I'm doing so any help would be greatly appreciated.

Thanks!

[url=http://feldoncentral.com/bbqcalculator.html?cc=0,0,200,0,0,0,46200.00,15400.00&fb=25.5,25.5,25.5,0,0,16581.38,15400.00,107.7&ch=6,829.07,29.34&fi=0,0,0,49.74,0&fc=13.00,18.38,132.65]Link to BBQ Pit Calculator[/url]

I think I need to make the firebox to cc opening 1.5x the measurement in the calculator. Is that correct?

Also is the vent stack ok at just under 30in?

I really have no idea what I'm doing so any help would be greatly appreciated.

Thanks!