Hello all!

I'm Dennie from The Netherlands. 26 y/o and working as a car mechanic

My english isn't that good, but i'm learning.

In my free time i like to build stuff out of junk.

I'm cooking on a el-cheapo offset smoker. 13 inch. Too small...but it's working great after i updated it with some extra metal.

So now i want to build something bigger, and better. So i picked up a old watertank. 300 Liters (80 gallons??)

In Holland we calculate in cm's. I don't understand how i should calculate in inches. It's a shame i know!

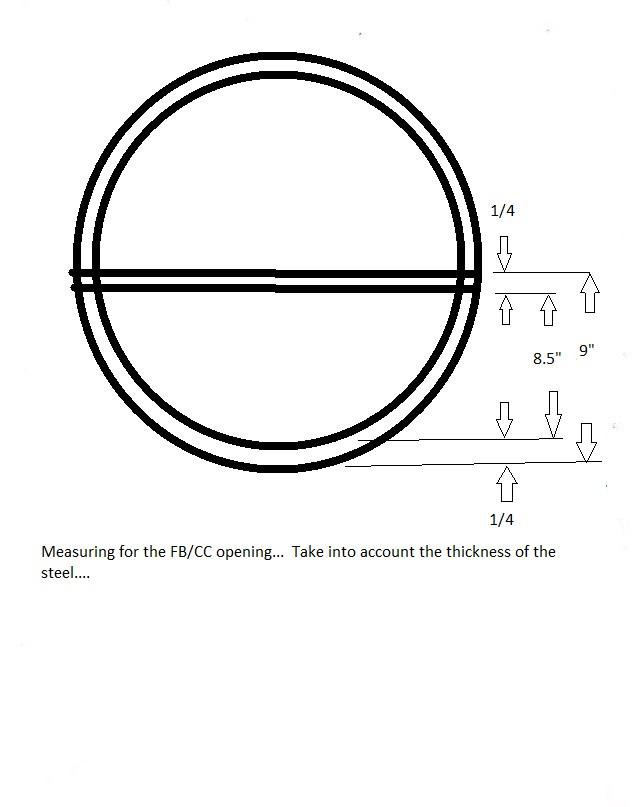

I hope someone can help me out with calculating the firebox.

My tank measurements Diameter 630 mm Capacity 300 liters Length 1245 mm

Greets!

Dennie.

I'm Dennie from The Netherlands. 26 y/o and working as a car mechanic

My english isn't that good, but i'm learning.

In my free time i like to build stuff out of junk.

I'm cooking on a el-cheapo offset smoker. 13 inch. Too small...but it's working great after i updated it with some extra metal.

So now i want to build something bigger, and better. So i picked up a old watertank. 300 Liters (80 gallons??)

In Holland we calculate in cm's. I don't understand how i should calculate in inches. It's a shame i know!

I hope someone can help me out with calculating the firebox.

My tank measurements Diameter 630 mm Capacity 300 liters Length 1245 mm

Greets!

Dennie.

Last edited: