Has anyone dropped the FB on their New Braunfels or OK Joes? It seems as though this one doesn't pull as much heat through to the CC as I feel it should and was thinking of unbolting the FB, dropping it down and welding it on instead of using bolts. I will very likely do a RF mod on it this winter and would like to tweak it to make a good smoker an awesome smoker

Dropping the fire box?

- Thread starter radio

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Thinking about dropping it where the heat will hit the top of the FB and flow directly into the CC. I will have to do some cutting and welding to make things fit and will most likely do a reverse flow mod at the same time. I need to plug some numbers into the cooker calculator before I start the job and see what openings I need.How far are you gonna drop it?

Radio,

I have done this mod on my NBBD.

I dropped the fire box by 3".

I used a 1/4" plate to mate the FB to the CC.

I brought the opening of the FB up to within 1/2" of the top of the FB and reduced the opening 30"sq.

I put in some baffle plates and it works great, I will change it to a reverse flow over the winter.

I would recommend dropping the FB.

All the best.

Karljohn.

I have done this mod on my NBBD.

I dropped the fire box by 3".

I used a 1/4" plate to mate the FB to the CC.

I brought the opening of the FB up to within 1/2" of the top of the FB and reduced the opening 30"sq.

I put in some baffle plates and it works great, I will change it to a reverse flow over the winter.

I would recommend dropping the FB.

All the best.

Karljohn.

Thanks for the info. The position of the FB does seem to high for maximum efficiency. When I do drop it, I will most likely weld it on instead of using bolts.Radio,

I have done this mod on my NBBD.

I dropped the fire box by 3".

I used a 1/4" plate to mate the FB to the CC.

I brought the opening of the FB up to within 1/2" of the top of the FB and reduced the opening 30"sq.

I put in some baffle plates and it works great, I will change it to a reverse flow over the winter.

I would recommend dropping the FB.

All the best.

Karljohn.

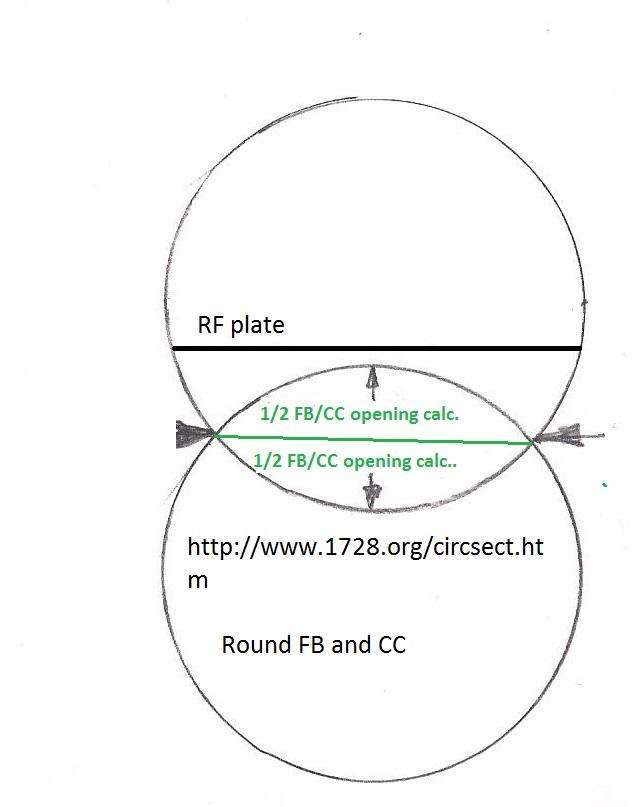

When figuring how far to drop it, I suggest calculating the CC volume and multiplying that number by 0.005 to get the FB/CC opening size... To figure the shape because you have a round CC and FB, use this shape.... That will give the best area to keep the RF plate low and provide the most area for cooking....

On a "normal" smoker build, I would suggest the factor be 0.004..... but due to the small size of the CC, the surface area to volume is high and steps need to be taken to reduce friction loss... thus the 0.005 factor....

...click to enlarge...

http://www.1728.org/circsect.htm

use radius and segment height to determine 1/2 the area (0.005 number) then flip the shape above the 1/2 area to make the football shape... Place the RF plate above the football shape....

On a "normal" smoker build, I would suggest the factor be 0.004..... but due to the small size of the CC, the surface area to volume is high and steps need to be taken to reduce friction loss... thus the 0.005 factor....

...click to enlarge...

http://www.1728.org/circsect.htm

use radius and segment height to determine 1/2 the area (0.005 number) then flip the shape above the 1/2 area to make the football shape... Place the RF plate above the football shape....

Last edited:

bob1961

Smoking Fanatic

I did that to my char broil SFB just like yours....

I added a piece of 1/8" plate to the FB and the CC....no welding, the bolt holes lined up nice Thumbs Up ....

I added a piece of 1/8" plate to the FB and the CC....no welding, the bolt holes lined up nice Thumbs Up ....

Last edited:

Radio,

Here is a picture of my finished NBBD.

I lined the inside of the firebox and the bottom of the CC with some SS that was going to be scrapped from work.

The increased weight meant that I had to make up a new frame.

If you look closely you can see the plate.

I will send some more pictures when I get a chance.

Karl.

Here is a picture of my finished NBBD.

I lined the inside of the firebox and the bottom of the CC with some SS that was going to be scrapped from work.

The increased weight meant that I had to make up a new frame.

If you look closely you can see the plate.

I will send some more pictures when I get a chance.

Karl.

Thanks KJ and Bob for the info and pics

Bob:It's hard to tell in the pic, but the opening from the FB to the CC looks a tad on the small side. Do you have any trouble getting higher temps when you need them?

When I do my NB, I will likely do a RF mod, although it might be smarter to do one mod at a time as two or more might make it difficult to ascertain which one is at fault in the event it doesn't cook well

Bob:It's hard to tell in the pic, but the opening from the FB to the CC looks a tad on the small side. Do you have any trouble getting higher temps when you need them?

When I do my NB, I will likely do a RF mod, although it might be smarter to do one mod at a time as two or more might make it difficult to ascertain which one is at fault in the event it doesn't cook well

bob1961

Smoking Fanatic

I did ribs in there after I dropped it down, held 240 solid for 6 hours with only 3/8" gap with the triangle intake opening these have....when I was done with the ribs I played with temps....opened the intake 2" and it got to 310 and held for the last hour when the coals died Thumbs Up ....I have 4 1/2" water drain holes in the fire box as well, I can cover them or open them for more or less draft for what temp I need....

Do you have a grate in the firebox for the wood/coals to rest on and draw air from underneath? If not, try putting a wire grate in the FB so the wood/coals are held above the bottom of the FB 4 to 6 inches and keep the ash cleaned out underneath so the air can keep the fire going. Most of the time my air intake is completely closed as it gets enough air to keep it going from the gaps around the FB door

I have that same smoker i can never get my temps steady! Also it kills the coals or flames when using wood if i close the lid.

Is your wood well seasoned? If it is still green it doesn't burn very well and can give the meat an acrid creosote taste. Is your smokestack open all the way? I run mine wide open and adjust the temp with the air intake. I find that partially closing the stack gives that strong creosote flavor to the meat, where leaving it open gives a much milder smokey taste.

I also used red rtv silicone to form a gasket around the CC lid and my temp stays very stable.

Good luck and keep us posted. There are many on here much more experienced than I, but we will help you get it figured out

bigholmes

Newbie

- Apr 9, 2014

- 19

- 10

it has grating that lifts the wood/charcoal.

Do you have a grate in the firebox for the wood/coals to rest on and draw air from underneath? If not, try putting a wire grate in the FB so the wood/coals are held above the bottom of the FB 4 to 6 inches and keep the ash cleaned out underneath so the air can keep the fire going. Most of the time my air intake is completely closed as it gets enough air to keep it going from the gaps around the FB door

Is your wood well seasoned? If it is still green it doesn't burn very well and can give the meat an acrid creosote taste. Is your smokestack open all the way? I run mine wide open and adjust the temp with the air intake. I find that partially closing the stack gives that strong creosote flavor to the meat, where leaving it open gives a much milder smokey taste.

I also used red rtv silicone to form a gasket around the CC lid and my temp stays very stable.

Good luck and keep us posted. There are many on here much more experienced than I, but we will help you get it figured out

Stack wide open and firebox vent full open.

Still can't get my temps up or a steady burn.

bob1961

Smoking Fanatic

well mine is almost a RF smoker now, bought some 1/8" plate for RF plate....just gonna sit it in there and see how it works....the RF opening is twice the size of FB to CC is....

I kept the same frame it came with and used a 2" L channel bolted to the legs to support the FB weight....

the weight of the FB is pushing on the L channel to keep it from moving....

just need to cut out the stack hole and move it mover and weld shut the old hole with piece I cut from here....

Thumbs Up ....

I kept the same frame it came with and used a 2" L channel bolted to the legs to support the FB weight....

the weight of the FB is pushing on the L channel to keep it from moving....

just need to cut out the stack hole and move it mover and weld shut the old hole with piece I cut from here....

Thumbs Up ....

can you post some pics of the smoker? the only other things I can think of that would cause temps to not be regulated would be CC lid not sealing or FB lid and/or door not sealing. The only place a smoker should be able to get air from is the adjustable air intake on the FB. If the rest of the smoker isn't sealed reasonably well, it can draw cool outside air into the CC through any gaps around the doorit has grating that lifts the wood/charcoal.

Do you have a grate in the firebox for the wood/coals to rest on and draw air from underneath? If not, try putting a wire grate in the FB so the wood/coals are held above the bottom of the FB 4 to 6 inches and keep the ash cleaned out underneath so the air can keep the fire going. Most of the time my air intake is completely closed as it gets enough air to keep it going from the gaps around the FB door

Is your wood well seasoned? If it is still green it doesn't burn very well and can give the meat an acrid creosote taste. Is your smokestack open all the way? I run mine wide open and adjust the temp with the air intake. I find that partially closing the stack gives that strong creosote flavor to the meat, where leaving it open gives a much milder smokey taste.

I also used red rtv silicone to form a gasket around the CC lid and my temp stays very stable.

Good luck and keep us posted. There are many on here much more experienced than I, but we will help you get it figured out

Stack wide open and firebox vent full open.

Still can't get my temps up or a steady burn.

I cant understand why you cant get the temp up with the air vent fully open. has the smoker been modified at all?

Perhaps some others will weigh in with ideas or suggestions

Looking good so far! That is pretty darned close to what I have planned for mine. Keep us posted on how she cooks after you get the stack movedwell mine is almost a RF smoker now, bought some 1/8" plate for RF plate....just gonna sit it in there and see how it works....the RF opening is twice the size of FB to CC is....

I kept the same frame it came with and used a 2" L channel bolted to the legs to support the FB weight....

the weight of the FB is pushing on the L channel to keep it from moving....

just need to cut out the stack hole and move it mover and weld shut the old hole with piece I cut from here....

....

bigholmes

Newbie

- Apr 9, 2014

- 19

- 10

Here you go.

can you post some pics of the smoker? the only other things I can think of that would cause temps to not be regulated would be CC lid not sealing or FB lid and/or door not sealing. The only place a smoker should be able to get air from is the adjustable air intake on the FB. If the rest of the smoker isn't sealed reasonably well, it can draw cool outside air into the CC through any gaps around the door

I cant understand why you cant get the temp up with the air vent fully open. has the smoker been modified at all?

Perhaps some others will weigh in with ideas or suggestions

You definitely need more wood/charcoal than I'm seeing in pic #3. I use a charcoal starter chimney almost full of briquettes and keep a couple of wood chunks 6 to 8 inches long and up to wrist sized on the fire and have to feed it another chunk or two about every hour. After 3 to four hours when the meat is about done absorbing smoke, I often just stoke the fire with fresh briquettes

I run the air intake either completely closed, or sometimes cracked about a half an inch

I run the air intake either completely closed, or sometimes cracked about a half an inch

bigholmes

Newbie

- Apr 9, 2014

- 19

- 10

Even with that amount if i close the lid on the firebox it goes out.

You definitely need more wood/charcoal than I'm seeing in pic #3. I use a charcoal starter chimney almost full of briquettes and keep a couple of wood chunks 6 to 8 inches long and up to wrist sized on the fire and have to feed it another chunk or two about every hour. After 3 to four hours when the meat is about done absorbing smoke, I often just stoke the fire with fresh briquettes

I run the air intake either completely closed, or sometimes cracked about a half an inch

The only way i seem to be able to get a good burn is with my wood stove fan.

its as if there is no air movenmet at all like it has stalled somewhere.

Check the stack for obstructions. Not likely, but there could be something blocking it. Build a test fire and try closing the upper air intake on the FB completely and leave the bottom one open. Do you have a thermometer with a probe? If you do, place the probe about mid way in the CC to get an accurate reading of the tempEven with that amount if i close the lid on the firebox it goes out.

You definitely need more wood/charcoal than I'm seeing in pic #3. I use a charcoal starter chimney almost full of briquettes and keep a couple of wood chunks 6 to 8 inches long and up to wrist sized on the fire and have to feed it another chunk or two about every hour. After 3 to four hours when the meat is about done absorbing smoke, I often just stoke the fire with fresh briquettes

I run the air intake either completely closed, or sometimes cracked about a half an inch

The only way i seem to be able to get a good burn is with my wood stove fan.

its as if there is no air movenmet at all like it has stalled somewhere.

Mine does not have the upper air intake, but I plan on making one when I lower the firebox as it keeps the heat from pooling in the FB and moves it into the CC more efficiently.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 0

- Views

- 632

- Replies

- 18

- Views

- 1K

- Replies

- 1

- Views

- 468

- Replies

- 15

- Views

- 4K

- Replies

- 16

- Views

- 688

- Replies

- 221

- Views

- 12K

Hot Threads

-

Our Second piece of Heaven, Little piece on the Atlantic Ocean

- Started by DRKsmoking

- Replies: 55

- General Discussion

-

How Do I Get Rid of These Armadillos?!!

- Started by seenred

- Replies: 41

- Blowing Smoke Around the Smoker.

-

Non fat dried milk

- Started by hog warden

- Replies: 37

- Sausage

-

Featured A couple thick strips please!

-

Getting to the bottom of what happens to cure in smoked sausage

- Started by hog warden

- Replies: 31

- Food Safety