For presents last Christmas I made 45 pounds of belly bacon using Montreal Steak Seasoning (MSS) as the primary flavor component. Everyone who got some really enjoyed it; some said it was the best bacon they ever had. The thread for that smoke is here: http://www.smokingmeatforums.com/t/132119/45-lbs-is-5-bellies

Today I brought home another box of bellies to make the MSS recipe again. There were five bellies in the box again, so I decided to freeze two of them for the next Christmas smoke of 7 bellies in November, and start curing the other three bellies tonight.

Last time I estimated that MSS was one-half salt. Instead of guessing again I decided to figure out the salt content of MSS from available information.

The mass ratios of Sodium and Chlorine in table salt is 39.3% Sodium, and 60.7% Chlorine.

Per the package nutrition panel, Montreal Steak Seasoning (MSS) has 170 mg of sodium per 800 mg serving.

At the mass ratio for the two elements in salt, 170 mg of sodium is bound to 262.57 mg of Chlorine, making 432.57 mg of salt, in one 800 mg serving of MSS.

Thus MSS is 54.07% salt.

To add 100 grams of table salt to a cure mix, you would add 185 grams of MSS.

To add 250 grams of table salt to a cure mix, you would add 463 grams of MSS.

To add 500 grams of table salt to a cure mix, you would add 925 grams of MSS.

So my previous guess of 50% was not far off the mark.

I'm using pink curing salt again this time. It is 6.25% sodium nitrate. The directions say to use 4 oz. with 100 pounds of meat. I will use this Dry Cure Bacon calculator: http://www.localfoodheroes.co.uk/calculator/dry_cure_bacon/

to determine the amount of table salt (contained in the MSS) to add to each slab of belly. I'm going to shoot for 2.25% salt content in the bacon.

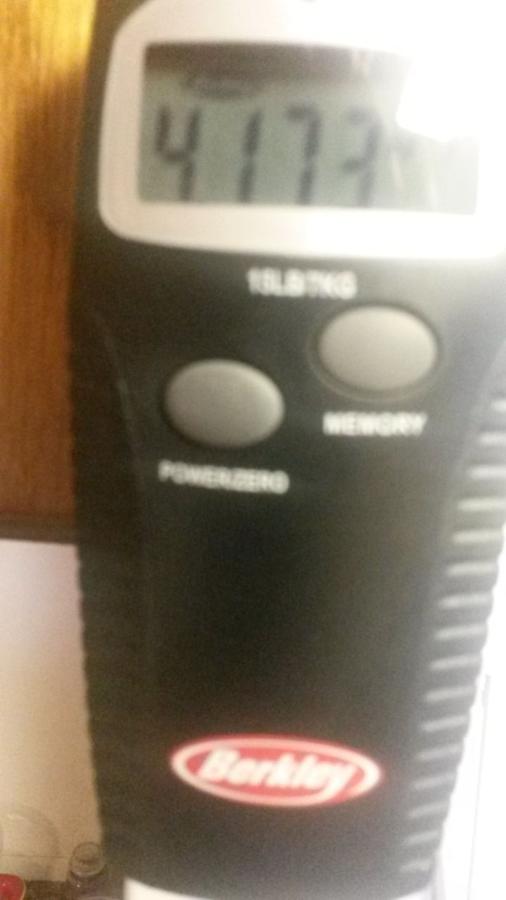

OK, so much for the intro. Now I'm off to weight each slab and calculate the cure mix for each piece. More to be posted soon.

Today I brought home another box of bellies to make the MSS recipe again. There were five bellies in the box again, so I decided to freeze two of them for the next Christmas smoke of 7 bellies in November, and start curing the other three bellies tonight.

Last time I estimated that MSS was one-half salt. Instead of guessing again I decided to figure out the salt content of MSS from available information.

The mass ratios of Sodium and Chlorine in table salt is 39.3% Sodium, and 60.7% Chlorine.

Per the package nutrition panel, Montreal Steak Seasoning (MSS) has 170 mg of sodium per 800 mg serving.

At the mass ratio for the two elements in salt, 170 mg of sodium is bound to 262.57 mg of Chlorine, making 432.57 mg of salt, in one 800 mg serving of MSS.

Thus MSS is 54.07% salt.

To add 100 grams of table salt to a cure mix, you would add 185 grams of MSS.

To add 250 grams of table salt to a cure mix, you would add 463 grams of MSS.

To add 500 grams of table salt to a cure mix, you would add 925 grams of MSS.

So my previous guess of 50% was not far off the mark.

I'm using pink curing salt again this time. It is 6.25% sodium nitrate. The directions say to use 4 oz. with 100 pounds of meat. I will use this Dry Cure Bacon calculator: http://www.localfoodheroes.co.uk/calculator/dry_cure_bacon/

to determine the amount of table salt (contained in the MSS) to add to each slab of belly. I'm going to shoot for 2.25% salt content in the bacon.

OK, so much for the intro. Now I'm off to weight each slab and calculate the cure mix for each piece. More to be posted soon.