So after alot of waiting and changes we finally have some progress on the new smoker build. Here is what has been done:

All the main component have been cut and awaiting assembly. Approximately 1200 lbs or raw steel!

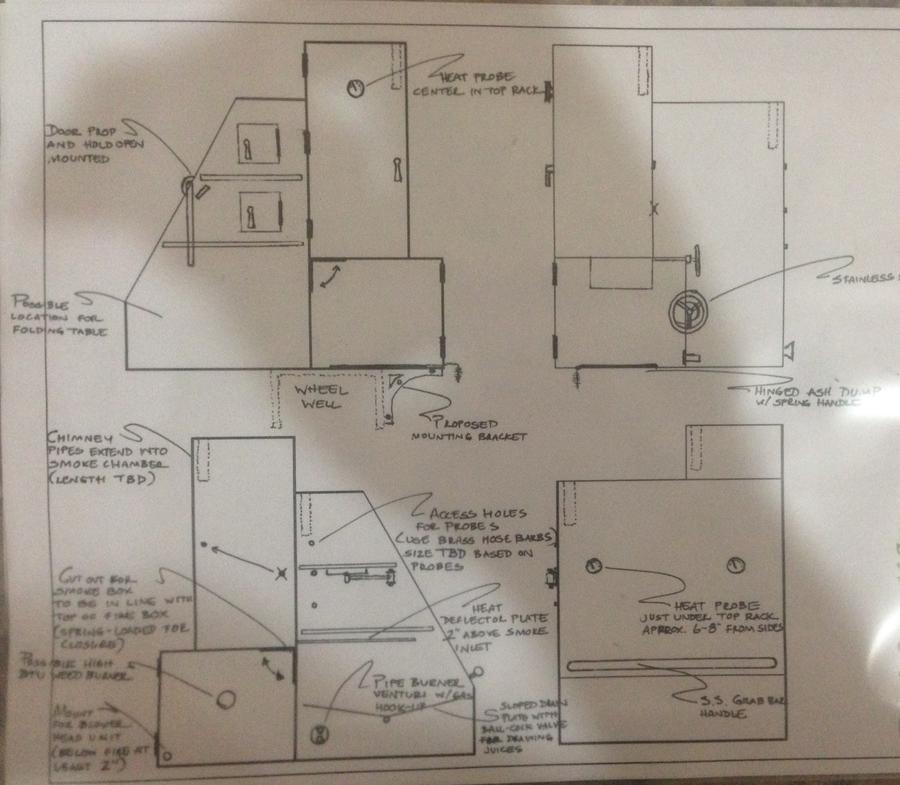

Started the work on the vertical cook chamber so that we could stack it right on once the main chamber was assembled.

Next up was to begin assembly of the main chamber and firebox.

The port on the side of the firebox is for a 25cfm stoker blower unit, I'm all about making things easier for me. Once we had everything true and square the construction of the main cook chamber and structure began to take shape.

We put 2 small view port doors on the right side of the main chamber to be able to inspect progress without opening the large main door (this should help maintain temps and smoke while giving me the ability to cheat peeks at the cooking process). Once the main structure I began fabrication on the fire pit door and wood rack.

With the main structure complete the next item to work on was the cooking grates and how they would fit into the main chamber.

I also addressed the issue of not wanting to burn tons of firewood on long cooks so we built a large pipe burner to mount at the bottom of the cook chamber. It made from 1-1/4" sch. 40 pipe, threaded and a large venturi mounted to introduce the gas.

With a board full of work it may be a while before any more progress is made. Next up will be the grease pan and drain, baffle plate, cook chamber doors and all the accesory fittings (i.e. probe inserts, mount for Stoker, door latch on firebox, handles...etc.)

Thanks for checking it out and any and all comments/suggestions are greatly appreciated!

All the main component have been cut and awaiting assembly. Approximately 1200 lbs or raw steel!

Started the work on the vertical cook chamber so that we could stack it right on once the main chamber was assembled.

Next up was to begin assembly of the main chamber and firebox.

The port on the side of the firebox is for a 25cfm stoker blower unit, I'm all about making things easier for me. Once we had everything true and square the construction of the main cook chamber and structure began to take shape.

We put 2 small view port doors on the right side of the main chamber to be able to inspect progress without opening the large main door (this should help maintain temps and smoke while giving me the ability to cheat peeks at the cooking process). Once the main structure I began fabrication on the fire pit door and wood rack.

With the main structure complete the next item to work on was the cooking grates and how they would fit into the main chamber.

I also addressed the issue of not wanting to burn tons of firewood on long cooks so we built a large pipe burner to mount at the bottom of the cook chamber. It made from 1-1/4" sch. 40 pipe, threaded and a large venturi mounted to introduce the gas.

With a board full of work it may be a while before any more progress is made. Next up will be the grease pan and drain, baffle plate, cook chamber doors and all the accesory fittings (i.e. probe inserts, mount for Stoker, door latch on firebox, handles...etc.)

Thanks for checking it out and any and all comments/suggestions are greatly appreciated!