Hi all. It has been a busy year for me so far. But, it's time to get back to building yet again. I learned a lot on my first RF build.... http://www.smokingmeatforums.com/t/...-build-125-gallon-propane-tank-plenty-of-pics

I learned that I would not fill up that smoker more than 2-3 times per year, which made it very inefficient for me to run. What I am looking for is a smaller, more efficient smoker that I don't have to 'babysit'.

I am absolutely sold on the RF design. (More smoke actually ON the meat and even temps.)

I'm looking to design & build a smoker that will be:

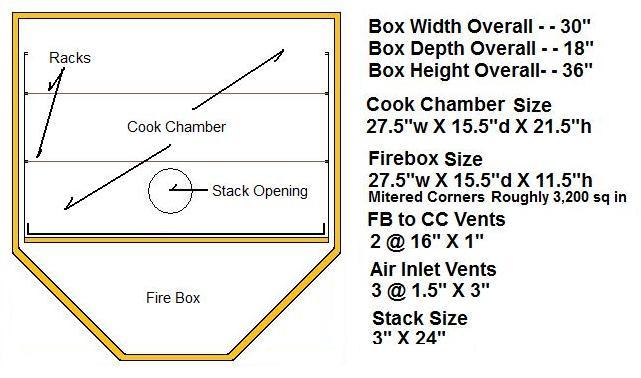

I started laying it out in general and haven't even got to the point of plugging the numbers into the calculator yet. When I get an electronic copy or two and a few numbers, I will post 'em.

Has anyone built such an animal?

I learned that I would not fill up that smoker more than 2-3 times per year, which made it very inefficient for me to run. What I am looking for is a smaller, more efficient smoker that I don't have to 'babysit'.

I am absolutely sold on the RF design. (More smoke actually ON the meat and even temps.)

I'm looking to design & build a smoker that will be:

- Coal Burner

- 750 - 1,000 square Inch Cook Surface

- Efficient (Fuel Burn, Footprint, Weight)

I started laying it out in general and haven't even got to the point of plugging the numbers into the calculator yet. When I get an electronic copy or two and a few numbers, I will post 'em.

Has anyone built such an animal?