- Jun 7, 2013

- 29

- 12

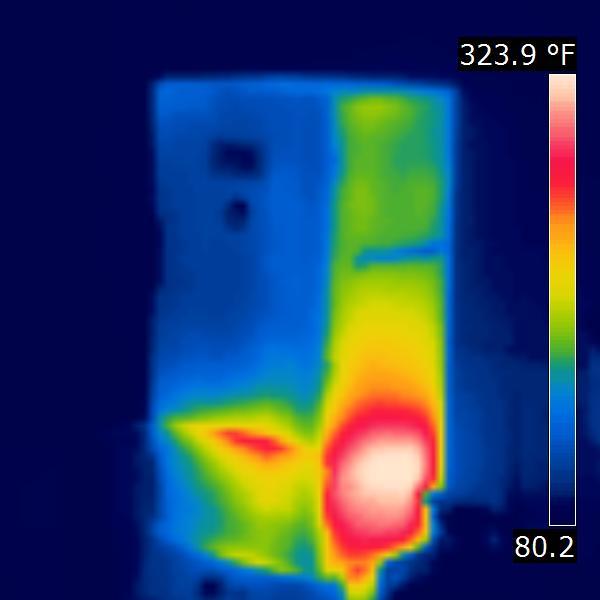

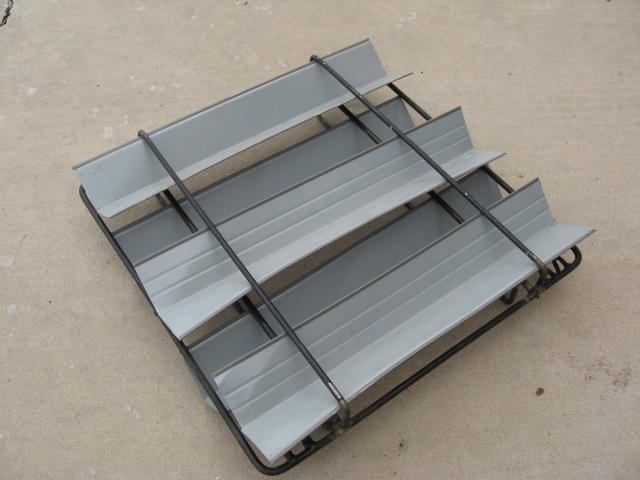

This is a thermal camera shot of my masterbuilt two door smoker, 250° inside going by the door thermometer and 80° ambient. These smokers come with a double wall on the doors, what I did do is seal the second wall with silicone to make an air insulated door. As you can see, the sealed second wall makes a good insulator. What I will use on the other sides is drip flashing that comes in 14 inch wide (and other widths) rolls at Home Depot.

On the two sides and top of the upper door (ran out of materiel) I put a copper seal from an old wood window. You can see it doesn't leak, you can see it's leaking badly between the upper and lower doors where there are no seals.

Did you guys know that regular silicone is rated for 400°? (service rating printed on package) Also food grade silicone only means if food comes in contact with the food.

On the two sides and top of the upper door (ran out of materiel) I put a copper seal from an old wood window. You can see it doesn't leak, you can see it's leaking badly between the upper and lower doors where there are no seals.

Did you guys know that regular silicone is rated for 400°? (service rating printed on package) Also food grade silicone only means if food comes in contact with the food.