Hey folks.

Getting ready to cut steel on a 200 gallon air compressor tank (built in 1963) to build a RF smoker and have a few questions. The calculator has been a big help in a potential design. It is 7ft long, 30 inches diameter, 3/16 in thick. I've looked through plenty of the threads, but maybe I've missed these. If they are repeats, I apologize.

I decided I don't need 7ft so I am going to cut 2ft off and use it for the firebox. I don't have access to a torch, so what would be the best method for cutting a straight line? I've got an angle grinder with cut off discs and they done well on cutting some of the welds off. Would this be enough? Maybe a circular saw with a cutoff disc? Suggestions?

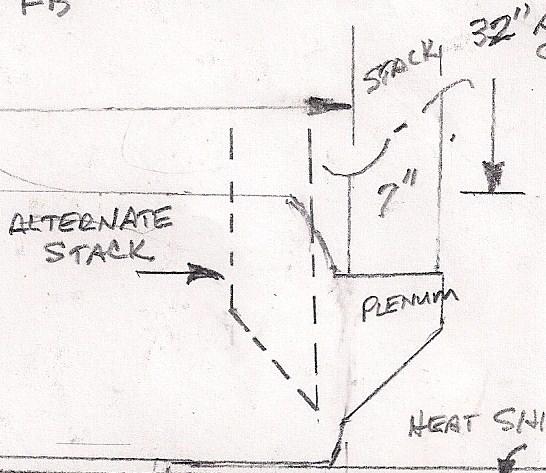

Will the section I cut off be enough for the firebox? Any reinforcement needed? According to the calculator, a 2 ft firebox on a 5 ft food chamber is 101% of what's needed. I am planning on getting two pieces of 30 in round steel, at least the thickness of the tank to fill in where it is cut and for the door of the firebox.

On the RF plate, how thick does it need to be? Also how big does the opening need to be from the RF plate to the food chamber. The calculator didn't mention it.

Any suggestions will be greatly appreciated.

Thanks folks.

Getting ready to cut steel on a 200 gallon air compressor tank (built in 1963) to build a RF smoker and have a few questions. The calculator has been a big help in a potential design. It is 7ft long, 30 inches diameter, 3/16 in thick. I've looked through plenty of the threads, but maybe I've missed these. If they are repeats, I apologize.

I decided I don't need 7ft so I am going to cut 2ft off and use it for the firebox. I don't have access to a torch, so what would be the best method for cutting a straight line? I've got an angle grinder with cut off discs and they done well on cutting some of the welds off. Would this be enough? Maybe a circular saw with a cutoff disc? Suggestions?

Will the section I cut off be enough for the firebox? Any reinforcement needed? According to the calculator, a 2 ft firebox on a 5 ft food chamber is 101% of what's needed. I am planning on getting two pieces of 30 in round steel, at least the thickness of the tank to fill in where it is cut and for the door of the firebox.

On the RF plate, how thick does it need to be? Also how big does the opening need to be from the RF plate to the food chamber. The calculator didn't mention it.

Any suggestions will be greatly appreciated.

Thanks folks.