Hi All:

I'm brand new to the Forum and have a few questions on my smoker that I've just finished. Its made out of 1 inch steel frame, stainless steel inside, insulated with aluminum on the outside. Still waiting for the nomex gasket to seal the doors.

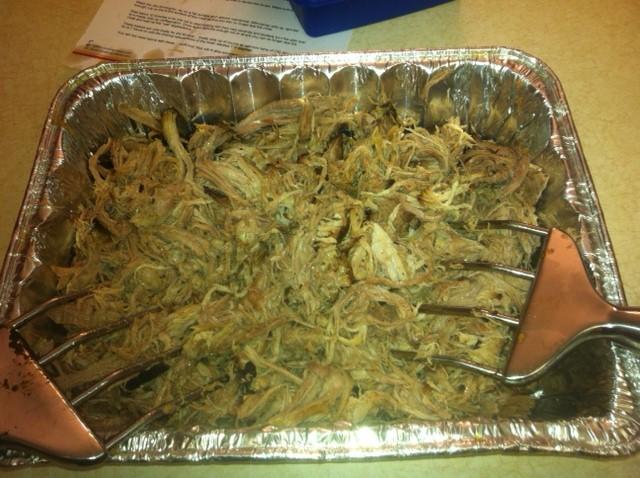

I'm using two small hot plates (1000W) but I can only get it up to 220 F. Will that be enough heat? I will be trying to do PP, Brisket, Turkey and Fish. When I have the smoker heating up the elements are red hot, however, when I open the door when it is up to temp (220) the elements are off. I've read on here, that some of these hotplates have thermal fuses that can be disabled to achieve more heat. Are there any tricks to disabling these hotplate thermal fuses?

Are there any other heat sources that I should look into?

.

Thanks for any tips in advance...

Denis

I'm brand new to the Forum and have a few questions on my smoker that I've just finished. Its made out of 1 inch steel frame, stainless steel inside, insulated with aluminum on the outside. Still waiting for the nomex gasket to seal the doors.

I'm using two small hot plates (1000W) but I can only get it up to 220 F. Will that be enough heat? I will be trying to do PP, Brisket, Turkey and Fish. When I have the smoker heating up the elements are red hot, however, when I open the door when it is up to temp (220) the elements are off. I've read on here, that some of these hotplates have thermal fuses that can be disabled to achieve more heat. Are there any tricks to disabling these hotplate thermal fuses?

Are there any other heat sources that I should look into?

.

Thanks for any tips in advance...

Denis