HARD FOR ME TO FIND MUCH TIME TO WORK ON THE SMOKER RIGHT NOW. I HAVE GOT A FEW THINGS DONE.

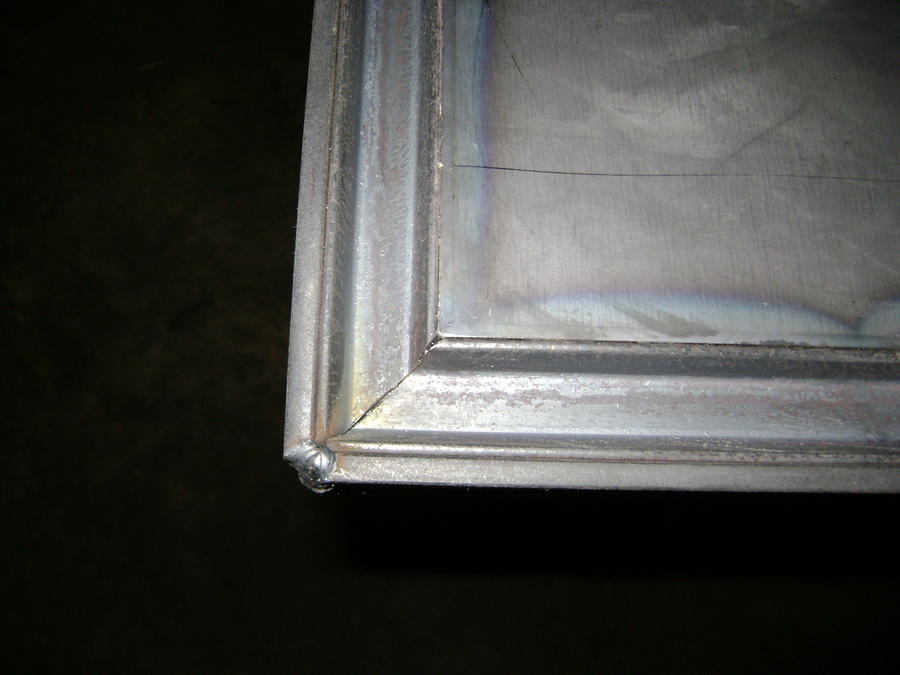

I GOT A GOOD START ON THE FIREBOX DOOR AND UPPER INTAKE. READY TO INSULATE. USED 1/4" PLATE FOR THE INSIDE OF THE DOOR AND WELDED IT TO THE CHANNEL FRAME. IT WARPED PRETTY BAD BY THE TIME I GOT IT ALL WELDED UP BUT I GOT IT PRETTY STRAIGHT NOW. GOTTA WELD THE 1/8" OUTTER SKIN ON. DOOR IS GONNA BE HEAVY. NEED TO DECIDE WHAT TO USE OR MAKE FOR HINGES.

I GOT A GOOD START ON THE FIREBOX DOOR AND UPPER INTAKE. READY TO INSULATE. USED 1/4" PLATE FOR THE INSIDE OF THE DOOR AND WELDED IT TO THE CHANNEL FRAME. IT WARPED PRETTY BAD BY THE TIME I GOT IT ALL WELDED UP BUT I GOT IT PRETTY STRAIGHT NOW. GOTTA WELD THE 1/8" OUTTER SKIN ON. DOOR IS GONNA BE HEAVY. NEED TO DECIDE WHAT TO USE OR MAKE FOR HINGES.