kcbluesnbbq

Meat Mopper

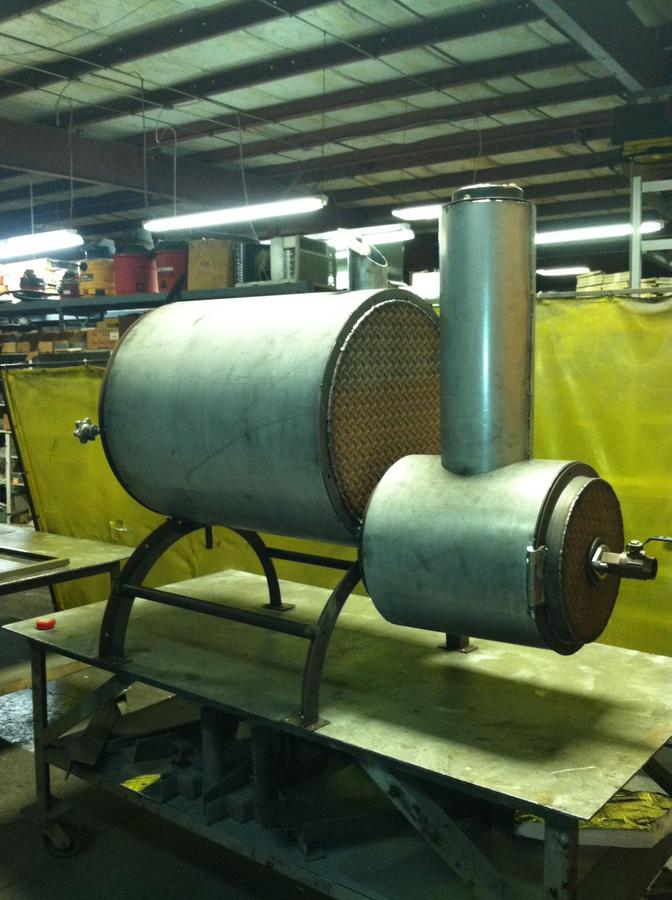

Looking good. I like the look. Kind of has an industrial refinery look.

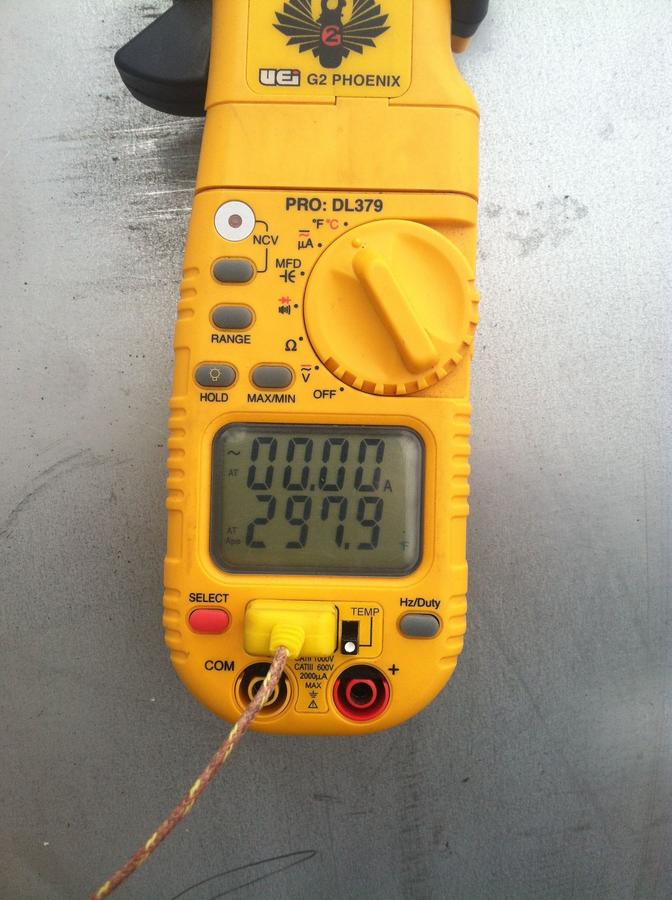

I have always wanted a gravity flow. Can't wait to see how well it works.

I have always wanted a gravity flow. Can't wait to see how well it works.