First build

- Thread starter berry1611

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Looking good...... You thinking about a cleanout drain in the cook chamber body ??? Just to wash out the ash and stuff ?? Now would be the time.... Dave

jabbo

Meat Mopper

Yes, on the clean out. Waiting on stainless angle to be shipped. Received stainless expanded sheet the other day. Now trying to decide on location of the cooker on the trailer that I have to build. The firebox is awful low so I think I will have to put the cooker up on the trailer to the passenger side and leave room on trailer for working in the middle of the trailer for the cooking rack area. Firebox can be feed from the ground level.

sunman76

Master of the Pit

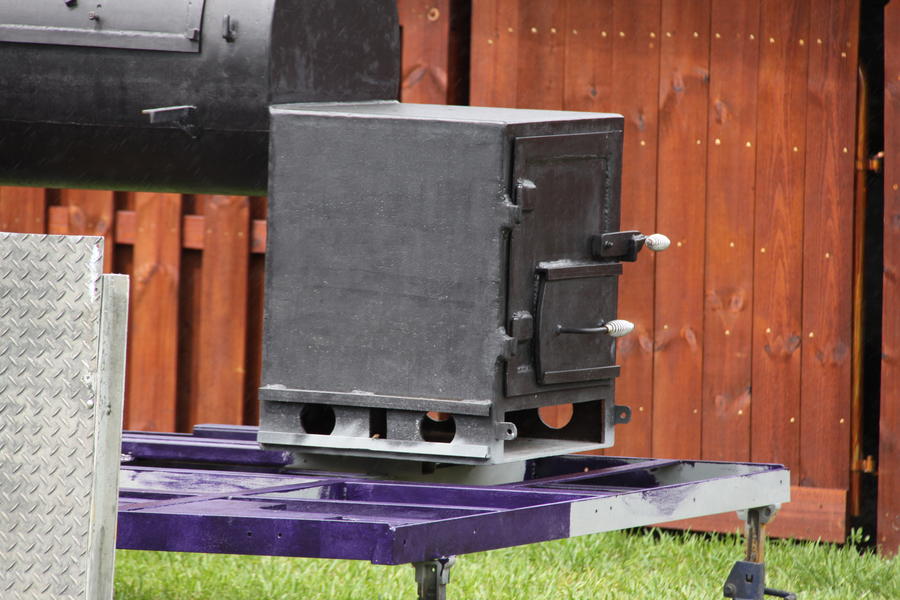

Hello all, I am still building the pit but work, family and rain has slowed things down. To bring everyone up to speed: the pit has been cooked on twice and the meat was good. Used alot of fuel on the 12 hour cook of brisket at 225 degrees. Now, I have decided to insulate the grill, ( cook chamber with ceramic wool fireblanket 2300 degrees rating and firebox 2" fireboard 1900 degree rating). Will cover insulation with sheet metal.

Trailer is built, primmed and cooker mounted to trailer. I uploaded photo's just before this was written. The metal weilded in the floor is to somewhat counter the weight of the cooker on the trailer. I made new hinges and they are installed now. Starting to frame out for insulation and will upload new photo's hopfully Monday or Tuesday. Aluminum diamond plate will be the flooring along with hand rails. The flooring and hand rails are from a old hunting buggy that I cut the top off.

Trailer is built, primmed and cooker mounted to trailer. I uploaded photo's just before this was written. The metal weilded in the floor is to somewhat counter the weight of the cooker on the trailer. I made new hinges and they are installed now. Starting to frame out for insulation and will upload new photo's hopfully Monday or Tuesday. Aluminum diamond plate will be the flooring along with hand rails. The flooring and hand rails are from a old hunting buggy that I cut the top off.

Berry, morning..... Think about an air inlet in the top center of the door, directly across from the FB/CC opening, to move heat from the FB to the CC.... That would help to reduce the wood consumption.... Then the air inlets below the fire grate will just burn the wood and not have to push air through the CC.... I'd make the upper air inlet about 4-6 sq. in. .....

One way to check if it will help in your smoker is check the temp of the FB... If it is over 300 deg or so, you are wasting heat in the FB... that upper air inlet will move that heat to the CC....

One way to check if it will help in your smoker is check the temp of the FB... If it is over 300 deg or so, you are wasting heat in the FB... that upper air inlet will move that heat to the CC....

Last edited:

Thanks Dave, I will put an air inlet inline with the CC in the FB door. Also, could my firebox be to big? I add 3" for the ash pan.

Dave, the firebox should be: pre the (bbq pit calculator) my height is 5" inches to tall and this puts me at 129.2% on the firebox. Now I did the raised stool grate design. That is way I made it taller to get air flow under the fire. If I need to cut 4 to 5 inches off I would like to do it before I insulate and cover the insulation up. THANKS.

maple sticks

Smoking Fanatic

"Thanks Dave, I will put an air inlet inline with the CC in the FB door. Also, could my firebox be to big? I add 3" for the ash pan."

Hi Berry, If your thinking of doing the air inlet it would be worth a try before insulating. You might find quite a difference in performance.

Hi Berry, If your thinking of doing the air inlet it would be worth a try before insulating. You might find quite a difference in performance.

Last edited:

jabbo

Meat Mopper

That firebox is a little on the big side, but it should be fine. There could be some draft issues, but I don't think it will be enough to cause problems. I believe, as long as you can control the heat inside it, it will work. More problems come from boxes being too small than too big. Too small means the fire may not be big enough to properly heat the CC. Too big just means more fuel for the fire. This could be a huge advantage if you use the minion method on long cooks. For shorter ones, just use less. Good job, brother.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 35

- Views

- 1K

- Replies

- 2

- Views

- 1K

- Replies

- 4

- Views

- 374

- Replies

- 33

- Views

- 1K

- Replies

- 5

- Views

- 2K

- Replies

- 230

- Views

- 12K

Hot Threads

-

Spammer PMs, Anybody Else?

- Started by chilerelleno

- Replies: 65

- Blowing Smoke Around the Smoker.

-

Questions for RecTeq owners

- Started by schlotz

- Replies: 64

- Blowing Smoke Around the Smoker.

-

Lost my dad yesterday

- Started by normanaj

- Replies: 40

- Blowing Smoke Around the Smoker.

-

On the Edge of Trying Sausage Making

- Started by BrianGSDTexoma

- Replies: 35

- Sausage

-

Took a stroll this afternoon

- Started by Buckeyedude

- Replies: 33

- Field and Stream