I started work on my smoker. Mostly prep work and cutting; in this case, prep work includes "getting 4300 lb of steel off the trailer." (Not all of it will be used for this smoker; I'm figuring roughly 1500 lb when I'm done.)

First step: get steel. 3/8" plate:

Lots of 3/8" plate:

Note the top plate--it's 8' wide, wide enough that I found I'd need to cut it down before I could move it off of the trailer. So cut I did...briefly:

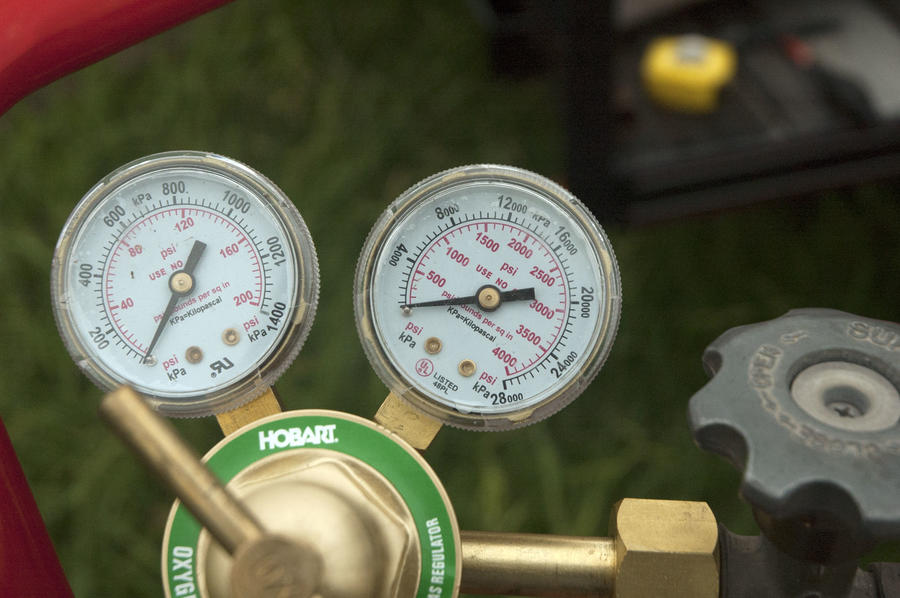

Hrm. Why did my cut suddenly go to crap, and where'd all that soot come from? Oh, that's why:

Guess I'll make a quick unscheduled trip up to

Back to work. I took about 3' off of that panel:

Still, they're awfully big and heavy. Fortunately, I have a solution:

That's about half-a-ton of plate right there. First time I've really used the bucket hooks; I'm glad my welds held.

As seen from the driver's seat. Right now, I'm bulletproof on the south side.

Ahh, all unloaded. Time for a

More next week when I start on the firebox; I need to get about 25' of 1" square tubing to frame out my firebox, as detailed at http://www.smokingmeatforums.com/t/126978/firebox-design-review-and-critique.

First step: get steel. 3/8" plate:

Lots of 3/8" plate:

Note the top plate--it's 8' wide, wide enough that I found I'd need to cut it down before I could move it off of the trailer. So cut I did...briefly:

Hrm. Why did my cut suddenly go to crap, and where'd all that soot come from? Oh, that's why:

Guess I'll make a quick unscheduled trip up to

Back to work. I took about 3' off of that panel:

Still, they're awfully big and heavy. Fortunately, I have a solution:

That's about half-a-ton of plate right there. First time I've really used the bucket hooks; I'm glad my welds held.

As seen from the driver's seat. Right now, I'm bulletproof on the south side.

Ahh, all unloaded. Time for a

More next week when I start on the firebox; I need to get about 25' of 1" square tubing to frame out my firebox, as detailed at http://www.smokingmeatforums.com/t/126978/firebox-design-review-and-critique.

Last edited: