There are lots of posts out there about folks "mailbox mods". Well after a lot of research, I decided to do my own version of a mailbox mod with an old mailbox I've had laying around.

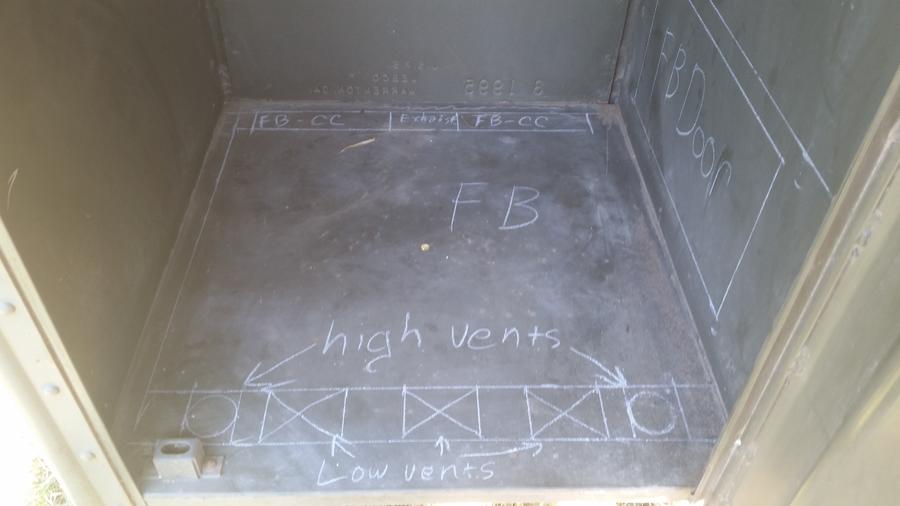

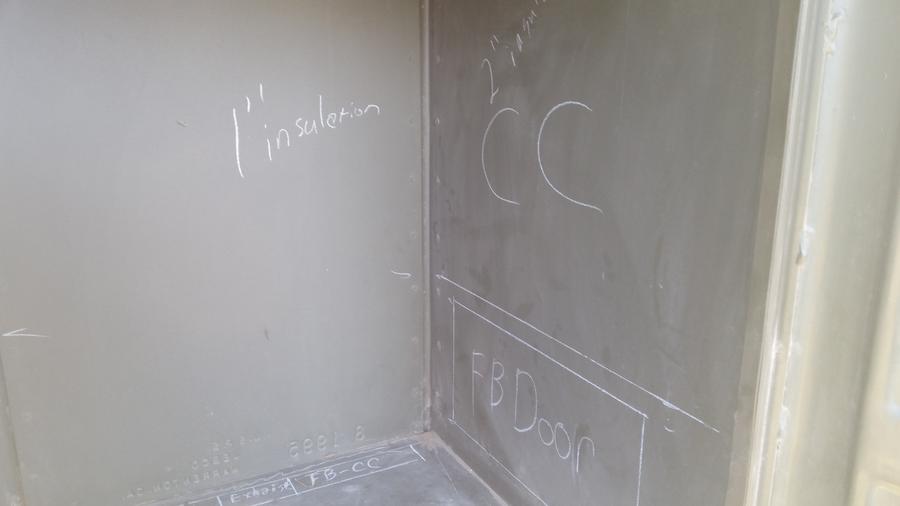

Ok, technically it's not a mailbox it's a US Mail Relay Box but it will work. So I decided on a vertical reverse flow.

Everything laid out and marked.

Since I am putting the door in the side of the box, I decided to put all my vents in the bottom front.

Have plenty of 1 1/4" ID pipe from old handrails laying around, so I will use this to get my high vents up where they need to be.

I think I have it worked out, but will take any suggestions from you experienced builders as this will be my first build.

Ok, technically it's not a mailbox it's a US Mail Relay Box but it will work. So I decided on a vertical reverse flow.

Everything laid out and marked.

Since I am putting the door in the side of the box, I decided to put all my vents in the bottom front.

Have plenty of 1 1/4" ID pipe from old handrails laying around, so I will use this to get my high vents up where they need to be.

I think I have it worked out, but will take any suggestions from you experienced builders as this will be my first build.