So I started Grad School and quit Grad School since I last posted. I have more free time now so I am back at it. I have missed some pictures along the way. I will share what I have.

Drilled hole for my drain pipe. Harbor Freight hole cutter plus cutting fluid works well. Don't have pictures but it took me a long time to get the drain water tight. I don't thing I took a picture out of embarrassment. It was mounds of ugly weld to get it right.

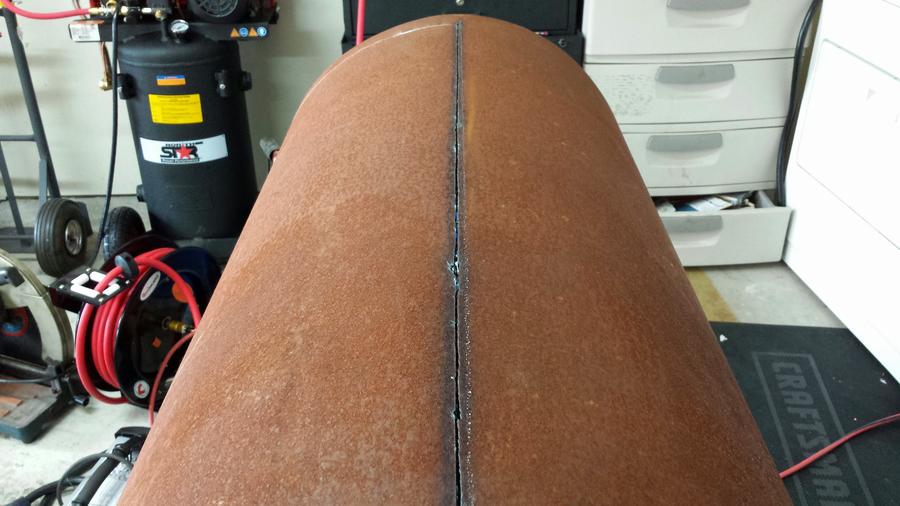

Cutting lid with plasma cutter. Never used one before. It is an amazing tool.

I decided to weld on the hinges.

Laid out lines for the side cuts.

attached a piece of angle to guide the cutter. Removed the hinges. I looked around on this site and decided to attach the hinges to the flange.

Position top flange

I welded the top and bottom flange on the door and finished cutting it out. Cut out RF plate. I was a good 1/2" higher than the drain. It took me many hours of grinding to get the plate to fit. Next time I will fit the plate first then make the drain meet the plate.

You can see the curved flange piece I haven't welded on yet.

After hours and hours of grinding I got the plate to fit. It slopes towards the drain. Plasma cut the drain hole.

Cut the slot a little wide. It is require some creative welding.

I used some cheap wood cardboard stuff from another project. This is the stuff they put on the back unseen side of dressers. I cut out a circle tracing my end cap. Got it to fit inside of the pit. I used that as a template and cut it out. After I made the template I decided to make it a little taller.

IT FIT, IT FIT, IT FIT!!!!!! This was the first thing i did that fit as it should the first time with no grinding. I guess this is what the measure twice cut once thing means.

There is my boo boo weld for my drain. You also see the RF plate welding in.

I am about to go out to the garage and snap some more picks and upload them later.

Drilled hole for my drain pipe. Harbor Freight hole cutter plus cutting fluid works well. Don't have pictures but it took me a long time to get the drain water tight. I don't thing I took a picture out of embarrassment. It was mounds of ugly weld to get it right.

Cutting lid with plasma cutter. Never used one before. It is an amazing tool.

I decided to weld on the hinges.

Laid out lines for the side cuts.

attached a piece of angle to guide the cutter. Removed the hinges. I looked around on this site and decided to attach the hinges to the flange.

Position top flange

I welded the top and bottom flange on the door and finished cutting it out. Cut out RF plate. I was a good 1/2" higher than the drain. It took me many hours of grinding to get the plate to fit. Next time I will fit the plate first then make the drain meet the plate.

You can see the curved flange piece I haven't welded on yet.

After hours and hours of grinding I got the plate to fit. It slopes towards the drain. Plasma cut the drain hole.

Cut the slot a little wide. It is require some creative welding.

I used some cheap wood cardboard stuff from another project. This is the stuff they put on the back unseen side of dressers. I cut out a circle tracing my end cap. Got it to fit inside of the pit. I used that as a template and cut it out. After I made the template I decided to make it a little taller.

IT FIT, IT FIT, IT FIT!!!!!! This was the first thing i did that fit as it should the first time with no grinding. I guess this is what the measure twice cut once thing means.

There is my boo boo weld for my drain. You also see the RF plate welding in.

I am about to go out to the garage and snap some more picks and upload them later.