I am in need of assistance again for another build.

This is for a woodburning stove for Winter Tent Camping. This will be used in a 11x20 tent on our Mancamp trip Next February to Green Ridge State Park, so I have some time.

I will be using a 40lb Fork Lift Propane bottle

I want to do a flat top but I am afraid of too much welding, the flat top would be for cooking and coffee and stuff.

These are not my photos.

I may just weld on a flat piece on top of the radius.

or something like this

The front would be designed like this one, keeping it simple

there would be a bottom piece for insulation instead of sand.

a grate would be above to allow airflow.

stack would be 4" sections stored inside stove, legs would be 1/2" threaded black pipe that screw into threaded caps or connectors that will be welded to the bottom.

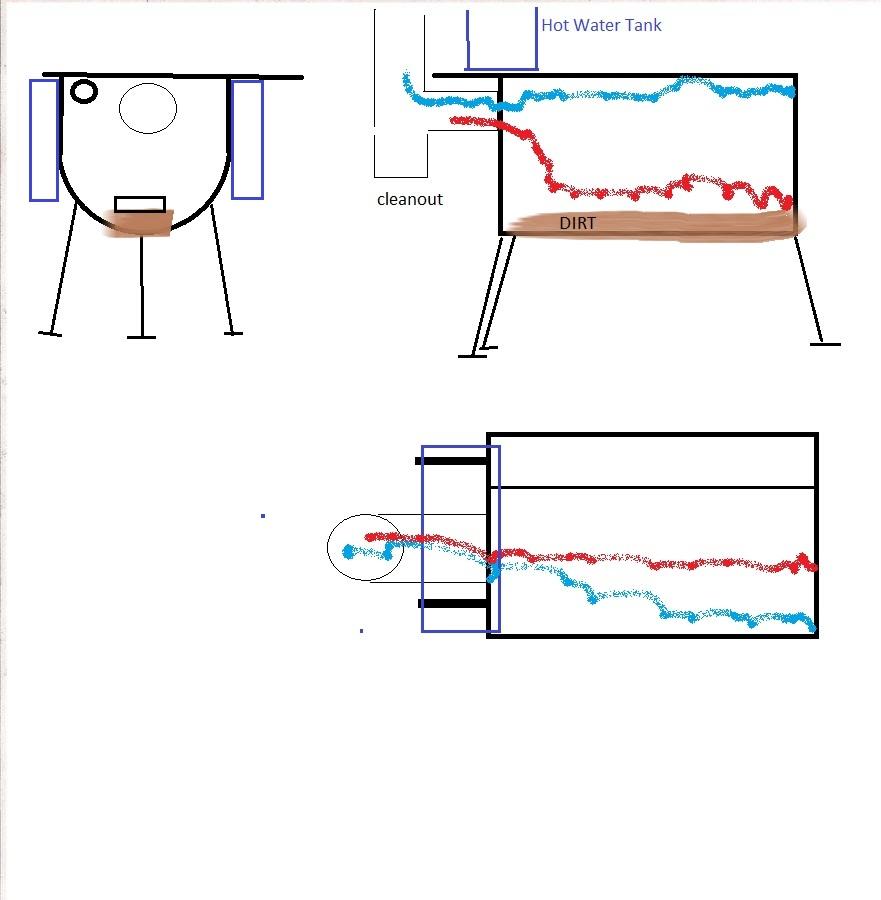

I will nee a baffle that sits below the stack hole so the heat has to go around the hole to exit, of course I will need a damper on the pipe and a spark arrestor.

I was thinking about a Stack robber, but the jury is still out on that one.

I can buy a cheapo for 65 or 70 bucks, but rather build a quality one customized to what I want.

This is for a woodburning stove for Winter Tent Camping. This will be used in a 11x20 tent on our Mancamp trip Next February to Green Ridge State Park, so I have some time.

I will be using a 40lb Fork Lift Propane bottle

I want to do a flat top but I am afraid of too much welding, the flat top would be for cooking and coffee and stuff.

These are not my photos.

I may just weld on a flat piece on top of the radius.

or something like this

The front would be designed like this one, keeping it simple

there would be a bottom piece for insulation instead of sand.

a grate would be above to allow airflow.

stack would be 4" sections stored inside stove, legs would be 1/2" threaded black pipe that screw into threaded caps or connectors that will be welded to the bottom.

I will nee a baffle that sits below the stack hole so the heat has to go around the hole to exit, of course I will need a damper on the pipe and a spark arrestor.

I was thinking about a Stack robber, but the jury is still out on that one.

I can buy a cheapo for 65 or 70 bucks, but rather build a quality one customized to what I want.

Last edited: